Stirring tooth fertilizer granulator is an efficient powder processing equipment widely used in modern industry, especially suitable for fertilizer production. It can convert powder raw materials into granules and produce high-quality granules in a short period of time. The automatic operation of this equipment not only improves the production efficiency, but also ensures the consistency of product quality. And that brings significant economic benefits for the enterprise.

How does the stirring tooth fertilizer granulator work?

The stirring tooth fertilizer granulator we developed is a kind of molding machine which can make the material into a specific shape. By mixing the powder raw materials with the binder and stirring them at high speed in the stirring container, the stirring blade’s shear effect makes the materials gradually gather to form wet mass. And then through the continuous stirring and tumbling, these wet masses grow to be primary particles. Then using a fertilizer screener machine to screen for right-sized particles and to the steps of drying, cooling and packing.

What’s the benefits of a stirring tooth fertilizer granulator?

Stirring tooth fertilizer granulator plays am important role in many fields, especially for fertilizer production. Using a stirring tooth fertilizer granulator can improve working efficiency and production quality greatly. The following are the benefits that you can get from a stirring tooth granulator.

Using high speed rotating stirring teeth to mix and granulate the materials, materials are quickly made into the required particles through mechanical force in a relatively short period time. And due to the unique design of the stirring tooth, the granulator can produce fertilizers in uniform shape and size and have a good fluidity. By producing fertilizers in this way, it makes easier for packaging and transportation. Therefore, using a stirring granulator machine not only increases the productivity, but also makes the quality of granules guaranteed.

Compared with the traditional wet granulation process, the stirring tooth granulator has lower water requirement in the granulation process. And it can reduce the energy consumption in the drying link. It can also reduce the potential waste of water resources in the granulation process. In a word, stirring tooth fertilizer granulator is a kind of environmentally friendly and energy-saving production equipment.

The simple design and compact structure of the gear stirrer makes it easier for the operator to adjust the parameters of the machine through the control panel to achieve optimal pelletizing results. What’s more, maintenance is also relatively simple, you only need to regularly check and replace the worn parts. And the cost of maintenance is also low, because the stirring tooth fertilizer granulator has a very long shelf life and you just need to change several parts.

In a word, stirring tooth granulator is a dispensable machine in modern industrial because of its unique advantages. It also plays a key role in various fields especially in pelletizing process where efficiency and environmental protection are required.

Which kind of stirring tooth granulator suits you better?

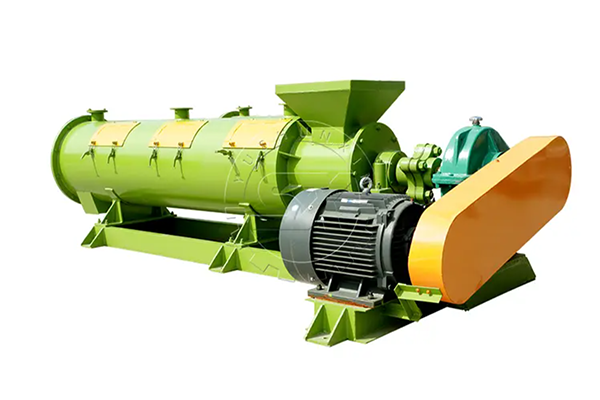

According to different demands, our company designed 2 kinds of different stirring tooth fertilizer granulators, they are new type organic fertilizer granulator and rotary drum churning granulator. Here is the information of the 2 granulation machines and you can choose the stirring tooth granulator based on your needs.

-

Granulator For Organic Fertilizer Granulation.

It’s a new kind of organic fertilizer granulation plant and has a wide of application that can deal with various kinds of organic waste. According to its own features, the price of a organic fertilizer granulator may be at $5,500~$8,000. The granulation rate of this kind of granulator is over 90% and you needn’t to add bactericide during the granulation process.

What’s more, it can save a lot energy for you because there is no need to dry in the process of granulator. And to some extent, it can save money for you. Because the new type organic fertilizer granulator has a low energy consumption. In a word, the new type organic fertilizer granulator is suitable for those who want to purchase a granulator with basic functions and less money.

-

Rotary Drum Churning Granulator With a Higher Granulation Rate.

If you want a granulator with a higher granulation rate, then a rotary drum churning granulator suits you better. Despite the price of the stirring tooth drum granulator in $7,000~$20,000 that cost you more, the granulator rate of the rotary drum churning granulator is over 97%. What’s more, it combines the granulation mechanism of stirring and rotating drum that can improve materials adaptability and granulation efficiency. And the key components are generally made of Q235B boiler steel, which can extend the service of the equipment.

How long does it take to pelletize in a stirring tooth fertilizer granulator?

Generally speaking, it usually needs 3-5 minutes to finish the process of pelletizing. And the pelletizing time of a stirring tooth fertilizer granulator depends on a number of factors, including the characteristics of raw material, quality and size of the pellets required, design of the pelletizing machine, and the operating parameters.

In the early stages of production, it may be necessary to determine the optimum pelletizing time through experiment. Because this is helpful to achieve the best pelletizing effect and production efficiency. After determining the optimum operating parameters, the pelletizing time is usually fixed and becomes part of the production process.