In modern agriculture, the use of fertilizer has a vital role in guaranteeing the growth of crops and improving production. And in order to ensure the quality and effect of fertilizer, there comes the fertilizer screener machine, which gradually becomes an indispensable part in agricultural production. Through efficient and precise screening technology, fertilizer screen machine can optimize product texture and appearance. In addition, with the development of technology, modern fertilizer screening machines are easier to operate and has a lower cost of maintaining.

What’s the working principle of fertilizer screener machine?

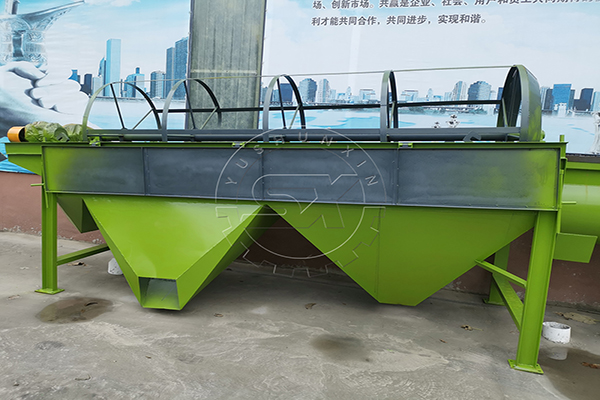

Rotary screening machine is mainly through an inclined and rotating cyclindrical screen body to classify and screen materials. And that can put the material from the high end and slides along the cylinder under the action of gravity rotation. And then it will discharge the qualified products from the lower part of the screen and the unqualified products from the lower end of the cylinder. This is helpful to realize effective separation and classification of materials. The fertilizer sifter is designed to handle a wide range of materials, whether granular substances or powdery fines. And it adapts and completes the screening operation quickly and efficiently, which ensure the classification and purity of the material. Fertilizer screener is widely used in many industries and favored for its high efficiency and easy operation.

How much does a fertilizer screening machine cost?

There are various factors influencing the price of a rotary screener, including screener machine’s size, function, application and other factors. You can use our fertilizer screener for screening granular and powdery fertilizers. And it will cost you about $1,000~$10,000. If you want to add some other functions like hitting function to reduce materials waste during shifting, you will have to pay more for $3,000. It can screens up to 20t of material per hour. What’s more, it also has a self-cleaning function. And that is helpful to reduce your maintenance costs and extend the service life of the machine.

What’s the difference between powdery screener and granular screener?

In order to improve the quality of fertilizer, you need to use a fertilizer screener to classify materials. And our company designed 2 different type of screening machines to sift granule and powder materials, which is helpful for you to choose the correct fertilizer screener you want. Here is the information of the 2 screening machines.

Different Application.

1. As the names show, you can use the powdery screening machine to sift fine dust-like materials, such as flour, chemical power, medical powder, and so on.

2. And using the granular screening machine is mainly to screen larger granular materials, such as sand, stone, fertilizer particles, food particles, etc.

Therefore, it is very important to choose the screening machine according to the state of different materials.

Different Design Features.

1. And there is a finer screener maching the powderr screener to prevent the leakage of tiny powder particles. Such screener may be equipped with vibration or ultrasonic systems to help the powder pass smoothly through the screen and prevent clogging.

2. Granular screening machines are designed with larger screens so that larger particles can be screened. Such screener may include different layers of screens for separating particles of different sizes. And generally speaking, the granular screener has 3 discharge ports that can screen different sizes of fertilizer quickly and efficiently. And you can combine it with granulating machine like stirring tooth fertilizer granulator and rotary drum granulation plant to produce high quality fertilizers.

To summary, choosing a correct fertilizer screener is vital to fertilizer production and is helpful to improve the efficiency of fertilizer production.

In conclusion, screening fertilizer after npk granulator plant not only guarantees the quality of product but also helps to reduce energy consumption and materials waste, which is beneficial to the process of fertilizer production.

What’s the capacity of the fertilizer screener machine?

The capacity of a fertilizer screener depends on a variety of factors, such as the size, type,and materials and so on. Our fertilizer screener can screen various kinds of solid materials with particles size below 300mm and the screening capacity is up to 20t hourly. It of made of corrosion-resistant materials that can be used for long service. At the same time, it also has the advantages of low noise, low dust emission and simple maintenance. In addition, you can also customize a fertilizer screener machine if the fertilizer screener doesn’t meet your requirements.

Why you choose a fertilizer screener machine during fertilizer production?

In the process of fertilizer production, fertilizer screener plays a vital role. It can screen out the standardized particles to ensure the consistency and quality of the product. What’s more, it can be able to recycle unqualified particles in order to re-pelletize. And that greatly improves the utilization rate of raw materials. At the same time, it can remove impurities and dust to improve the final product quality. In addition, it also helps to reduce wear and tear on subsequent packing and transportation equipment. What’s more, it can provide operators with instant feedback on pelletizing results and make the production process more efficient and controllable. To conclude, the fertilizer screening machine is the key to ensure the high efficient operation and produce high quality production.

Content

- What’s the working principle of fertilizer screener machine?

- How much does a fertilizer screening machine cost?

- What’s the difference between powdery screener and granular screener?

- What’s the capacity of the fertilizer screener machine?

- Why you choose a fertilizer screener machine during fertilizer production?