In the past few years, the government of Brazil committed to improving crops yields and agricultural competitiveness. On February 10th, 2024, a customer from Brazil found us and expressed their requirements of organic fertilizer production line. Based on their requirements, we provided our solutions with 5 organic fertilizer production machines.

What’s the detailed needs of the organic fertilizer line that our Brazil customer mentioned?

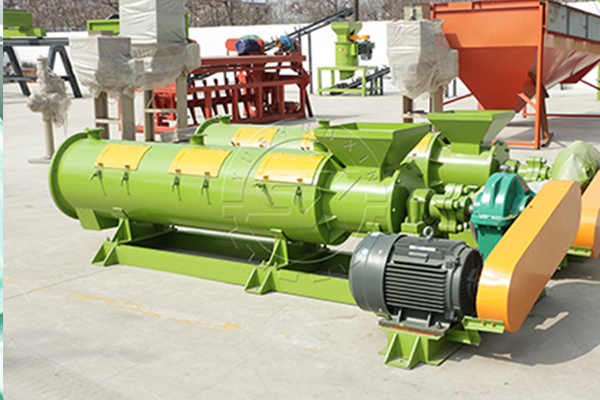

At first, the Brazilian customer indicated that they currently own a plant that produces organic fertilizer. And the main production process used in the plant is granulation technology. With the change of production demand and the development of the market, the customer plans to upgrade the existing granulating line to transform it into a more efficient pellet line. During the conversion, they had great interest in some key fertilizer production machine, especially the new type organic fertilizer granulating machine, drum drying machine and fertilizer screener machine. They wanted these machines can handle materials about 5-7 t/h. In addition, they mentioned they have equipped some auxiliary equipment. Therefore, they need some new equipment for organic fertilizer production line.

What’s the configuration of the organic fertilizer production line?

Considering Brazilian customer’s needs, we tailored a fertilizer production line comprising a fertilizer granulator, a high-efficiency drying machine, and some auxiliary equipment. The new type organic fertilizer granulating machine can granulate fertilizers with a granulation rate over 90%, which is beneficial to improve the fertilizer quality. What’s more, it can produce 8t fertilizers in an hour. And the fertilizer granulated by a new type organic fertilizer granulating machine has a high hardness. In addition, the whole granulating process is under a closed condition that produces few pollution and dust. Using a fertilizer screener can sift out substandard fertilizers to improve the whole fertilizers quality. And a fertilizer drying machine is helpful to improve the hardness of fertilizer, which benefits storage and transportation. This production line is not only capable of producing 5-7 tons of fertilizer per hour but also enhancing operational efficiency through the seamless integration and coordination.

How much does the 5-7 t/h organic fertilizer production line cost?

The organic fertilizer production solution we provided our Brazil customer is an intact fertilizer production line and it includes key fertilizer production equipment. Commonly, the price of an organic fertilizer production is usually at $20,000~$90,000 because of different production capacity and function. And based on the production needs of 5-7 t/h, our Brazil customer paid about $55,000 for such an organic fertilizer granulation plant. In a word, the total expense, including the price of fertilizer production line itself and transportation expense, it cost them about $60,000. And if you are interested in our fertilizer equipment, please contact us.

How long does it cost to transport the organic fertilizer production line to Brazil?

The first stage of transporting an organic fertilizer production line from China to Brazil starts take about 1-3 days. This stage starts with the initial preparation and domestic transport from the factory to the nearest Chinese port. Next, the the cargo undergoes customs clearance in China, which takes about 1-3 days. Once cleared, all the machines are loaded onto a ship for a sea trip. And according to the different route, it will cost 20-40 days to transport. After the machines arrive at the Brazilian port, they need to go through the local custom clearance procedures. This step usually needs 1-5 days. Finally, a truck will transport the production line to the intended destination within Brazil. And it mainly needs 1-5 days to complete the international shipping process. In a word, the whole process of transporting an organic fertilizer production line from China to Brazil needs 30-60 days.