Rotary drum granulation plant, as an indispensable equipment in modern industrial production, is mainly used to process powdery materials into regular granular products. Because of its high efficiency, low energy consumption, simple operation and high quality of output particles, it has become the preferred equipment in the fertilizer granulation process. What’s more, if you combine the rotary drum granulator with npk granulator plant, it can increase your profits.

How does the rotary drum granulation plant work?

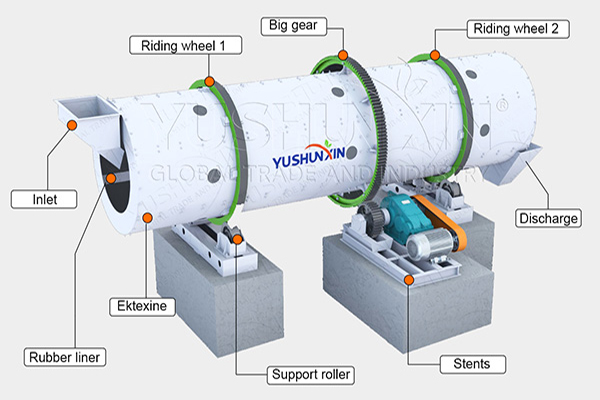

The rotary drum granulator mainly uses wet granulation method based on the mixing and granulating process of materials through rotary movement inside the drum. The core component is a cylindrical drum placed at an angle and rotating slowly.

How much does a rotary drum granulation plant cost?

In addition to the factors above, when you considering purchase a rotary drum granulator you should consider other factors, like the cost of manufactures, after sales services, and transportation and installation.

What’s the application of rotary drum granulation plant?

By granulating, it helps to keep the nutrients evenly distributed and allow for a more even distribution to crop when applying the fertilizer. In addition, rotary drum granulator can help to improve the strength and compression resistance of granules during granulation. This can ensure that fertilizers are unbreakable during storage and transportation, reducing the generation of dust and fines.

By granulating, it helps to keep the nutrients evenly distributed and allow for a more even distribution to crop when applying the fertilizer. In addition, rotary drum granulator can help to improve the strength and compression resistance of granules during granulation. This can ensure that fertilizers are unbreakable during storage and transportation, reducing the generation of dust and fines.

What rotary drum granulator is suitable for the yield of 40t?

The largest production of our drum rotary granulator can reach to 30t/h. In addition, the capacity is different according to different models and power. And if you want a rotary drum granulator to produce 40t fertilizers one hour, we suggest you to buy 2 SXZGZ-3210 granulators. It’s the largest rotary drum granulator in our company that not only meets to your production needs of 40t/h but also you can use it to produce large yield of fertilizer.

| Model | Power(kw) | Diameter(mm) | Length(mm) | Installation Angle(°) | Rotary Speed(r/min) | Capacity(t/h) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5 | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5 | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5 | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5 | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5 | 9.5 | 15-30 |

Why you choose SX to buy a rotary drum granulation plant?

We are a company specializing in the production of machinery and equipment. And we have a professional research and development team and technical support, so buying our rotary drum granulator is a good choice for you.