NPK granulator plant is dispensable and key in agricultural production, which is used for producing nutrient-rich and effective compound fertilizers. It integrates a wide range of nutrients such as nitrogen, phosphorus and potassium. And that is helpful to enhance the efficiency of fertilizer and reducing environmental impact. With the advancement of technology, these machines are becoming more efficient and environmentally friendly and are an important symbol of modern agricultural.

How to produce NPK fertilizer?

NPK compound fertilizers are an important part of modern agriculture, which providing crops with essential nitrogen, phosphorus and potassium nutrients. The NPK pelletizing line mixes nutrients in scientific proportions and transforms them into granular fertilizers that are easy to use and store through an efficient process. The following is the specific process of NPK pelletizing production.

These are just the basic steps of compound fertilizer granulation. If you want to improve the quality of NPK fertilizer, you can use a fertilizer polishing and a coating machine. If you have any problems, you can contact us, we will you our best solutions.

-

Choosing a NPK Fertilizer Granulation Machine Based On Different Production Scale.

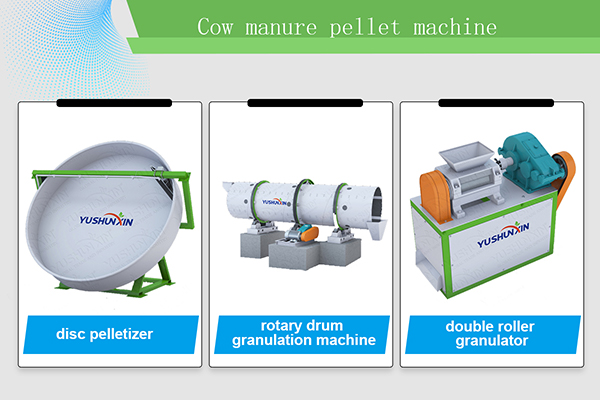

Choosing a NPK fertilizer granulator according to your production scale is the most cost-effective method. Our company can provide with you the granulator you want. If you have a large need for NPK fertilizer, then the rotary drum granulation plant in our company suits you better. Although it cost you $7,000~$70,000 that is much than other graulators, it can produce fertilizers about 1-30t one hour. It is very suitable for large scale fertilizer production. What’s more, it made of abrasion and corrosion resistant material and has a long shelf life. Our company also sells small and medium scale granulator, therefore, if your need for NPK fertilizer is smaller, you can choose disc granulator. It only takes you $1,000~$16,000 and granulates 6t materials in one hour, which is perfect for low demand with limited budgets.

-

Choosing a NPK Fertilizer Granulator Based On Production Efficiency.

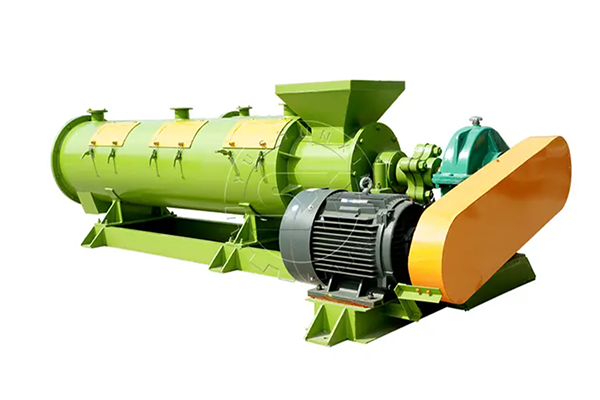

If you want to produce NPK fertilizers in a short time, our company can provide with you a stirring tooth fertilizer granulator. And it only needs $7,000~$25,000. It can finish a batch of fertilizer production within 5 minutes. It adopts the method of the rotation of drum and stirring teeth for pelletizing. That can greatly improve the efficiency of pelletizing. What’s more, it has a high granulation rate over 97% that can produces high quality NPK fertilizers for you.

-

Choosing a NPK Fertilizer Granulator Based On Your Budget.

If your budget is not enough but want to purchase a fully functional NPK granulator plant, we suggest you buy a double roller granulation machine. Double roller granulator adopts dry granulation method, which not only produces fertilizer efficiently but also does not need to be dried and cooled. And roller compactor granulator costs $3,000~$12,000. Therefore, the use of roller granulator can help you save money on purchasing dryer and cooler, but also shorten the granulation cycle and improve production efficiency.

How to reduce pollution during NPK fertilizer granulation?

The process of compound fertilizer granulation production will produce waste water and exhaust gas, which not only pollute the environment, but also threaten the health of operators. Therefore, it is very necessary to take measures to reduce pollution. In order to reduce the pollution to environment and protect employees’ health, you can take measures from the following aspects.

What NPK granulator plant is suitable for the yield of 40t?

If you have a much larger need for NPK fertilizer production of over 40t, you can purchase 2 rotary drum granulator. On the one hand, it can produce 60t NPK fertilizer one hour that meets to your needs. On the other hand, it can be used for larger scale production. What’s more, you can also combine a disc pelletizer with a drum granulator. Firstly, it can meet your requirements. What’s more, it combines the advantages of the two granulators and is conducive to improving production efficiency and fertilizer quality. Therefore, if you have large needs for NPK fertilizer production, the 2 methods above can help you.