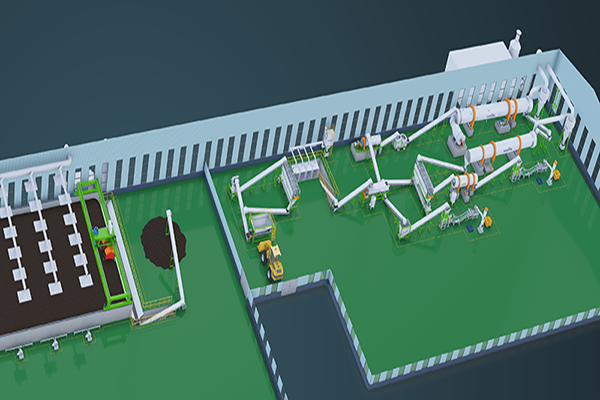

Organic fertilizer granulator plant, as an indispensable equipment for modern agriculture, has attracted wide attention. It uses advanced technology to convert organic waste into fertilizer granules that are easy to store and use. And using organic fertilizer granulation plant can reduce environmental pollution and improves soil fertility and crop yields. Next, we will introduce the working principle and application of organic fertilizer granulator.

What’s the price of organic fertilizer granulation plant?

The price of organic fertilizer granulation plant varies a lot depending on various factors. As a key step in organic fertilizer granulation, the choice of granulator is very important. Here is the information of the price of different types granulator machine for your reference.

The information is only for reference, and when you deciding to purchase an organic fertilizer granulator machine, you should also consider other factors like your budget, additional functions and services.

What’s the application of organic fertilizer granulation plant?

- The organic fertilizer granulation plant has a wide range of application and you can use it for the following areas.

- Firstly, organic fertilizer granulation plant can deal with agricultural waste, such as crop stalks, leaves, grass clippings, animal manure. It can be also used for livestock and poultry farming granulation. Mixing livestock and poultry manure with agricultural waste and processing then into organic fertilizers. This is helpful to reduce the spread of malodors and disease microorganisms and increase the economic value of the fertilizer. And you can use organic fertilizer granulation plant to handle urban organic waste and gardening fertilizer.

- Organic fertilizer granulator has a wide range of applications, therefore, you can use it to granulate different raw materials, which is helpful to improve the utilization rate of the granulator. And at the same time, it can also help you reduce unnecessary expenses.

Why you choose SX to buy an economic organic fertilizer granulator plant?

In addition, we have professional after-sales service that we can provide installation service. Most importantly, our machines are made of wear-resistant and corrosion-resistant materials and will work for you for ten years. Our machines are easy to operate and the maintenance costs are low, therefore, you don’t have to spend a lot of effort maintaining them. In short, choosing us to buy pelletizing machine is your best choice.

How long does it cost of granulating organic fertilizer?

The granulation process of organic fertilizer generally includes the steps of composting and fermentation, crushing, mixing, granulation, drying and cooling, and packaging. It takes only 15-20 days to ferment using a composting machine. And the granulation time will be different because of the different granulation methods, granulation requirements and granulator function, etc. Generally, the granulator can complete a batch of organic fertilizer granulation within 10 minutes. In short, using our company’s granulator can help you granulate quickly and efficiently. Meanwhile, choosing the right granulator is also helpful to improve the quality of fertilizer granules.