Cow manure fertilizer pellet machine is an important agricultural equipment that transforms cow dung into efficient fertilizer. This not only provides an environmentally friendly solution for farm waste management, but also converts organic waste into reusable resources. With the rise of sustainable agricultural practices and awareness of environmental protection, cow manure pelletizers play a vital role in modern agricultural production. In the following discussion, we will delve into the working principle, operation and application of cow manure pelletizer.

How to deal with cow manure?

Cow dung pelletizing process is the process of converting cow dung, an organic waste, into organic fertilizer pellets after treatment. This process not only helps to solve the problem of manure disposal in farms, but also converts the waste into valuable resources. The following is the basic process and key steps of cow manure pelletizing.

These are the basic steps of cow dung granulation, and if you want to improve the quality of cow dung fertilizer, you can use a fertilizer polishing machine and a fertilizer coating machine.

How to choose a suitable cow manure fertilizer pellet machine?

In the pursuit of sustainable agricultural development, it has become an important issue for farm managers about how to effectively convert and utilize cattle manure resources to reduce environmental pollution. As an important tool of deal with such problem, cow fertilizer pellet machine not only converts cow dung into organic fertilizer pellets but also improves fertilizer utilization. Therefore, if you don’t know how to select a suitable cow manure fertilizer granulator, just follow us.

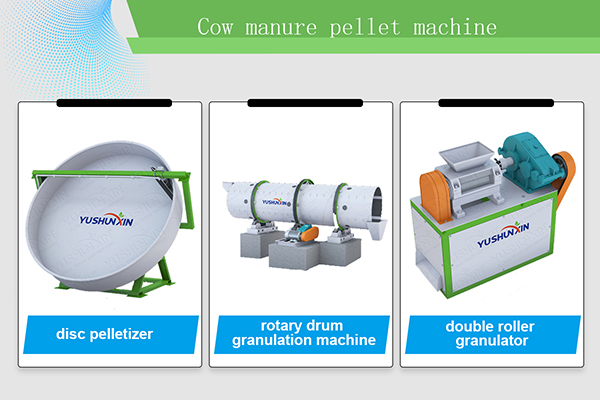

If you have a high demand for cow manure pellets then a rotary drum granulator suits you better. It can pelletize 1-30t cow dung fertilizer pellet one hour, which can meet your needs. And it has a long shelf life and low maintenance cost, such a granulator costs you $7,000~$70,000. We also have other granulation machine for small scale fertilizer production line. Therefore, if you have a low demand for cow manure pellets, we suggest you purchase a disc granulator. And it can produce 6t fertilizers one hour, its price is at $1,000~$16,000. Therefore, if you don’t need a lot of cow manure fertilizer pellets and want to save money, it is the right choice for you.

If you have higher demand for cow manure pellets, then you can choose a rotary drum churning granulator. Because it can produce fertilizer within 5 minutes and have a high granulation rate over 97%. All in all, it can not only produce fertilizer quickly and improve working efficiency, but also guarantee the quality of the fertilizer. And it will cost you about $7,000~$25,000.

Rotary drum pelletizer, organic fertilizer pelletizer and churning drum pelletizer are the 3 main models of cow dung pelletizer that our company promotes. If you have enough budget, we suggest you purchase rotary drum granulator, which will cost you $7,000~$70,000. Although it costs much compared with the other 2 granulation machines, it can produce large scale fertilizers quickly. And if your budget is not too much, you can buy an organic fertilizer granulation machine that costs you $1,000~$16,000.

These are just the references we provide for you, in the actual choice you can choose according to your needs.

What’s the benefits of cow manure fertilizer pellet machine?

Cow manure fertilizer pellet machine can efficiently convert cow dung into granular organic fertilizer. Through the conversion process, it can effectively reduce the humidity of cow dung and reduce the volume. And it’s easy to store and transport. At the same time, it can kill germs and reduce the pollution of the environment. In addition, cow dung granulator is easy to operate, and it has low maintenance costs, which is an environmentally friendly and economical organic fertilizer equipment.

How to improve the quality of cow manure pelletizing?

If you want to improve the quality of cow manure pellets, then you need to carefully control each production process.

-

Pelletizing cow dung.

Secondly, when pelletizing, you can add a rounding machine. This can make the fertilizer particles more uniform and smooth. After drying and cooling, the fertilizer is strictly controlled and improve the standard of fertilizer. The unqualified ones can be sifted by the sieving machine and then crushed, and repeat the steps like mixing and granulating. For qualified fertilizer particles can choose to use the coating machine. This is more conducive to the storage and transportation of fertilizer. And last, packing fertilizer.