In May 2025, a Nigerian client contacted SX for a cost-effective solution to use chicken dung as organic fertilizer. Facing challenges in manure management and local soil degradation, the client needed a reliable production line that fits both budget and site conditions. After communication, YUSHUNXIN provided the customer in Nigeria with a complete dry chicken manure fertilizer granulation production line.

The requirements of Nigerian customers for the chicken manure fertilizer production line?

Dry vs Wet Granulation: SX Delivers Chicken Dung Fertilizer Solutions in Nigeria

To meet different production goals and budget expectations, SX designed two complete chicken manure fertilizer production solutions for the Nigerian client.

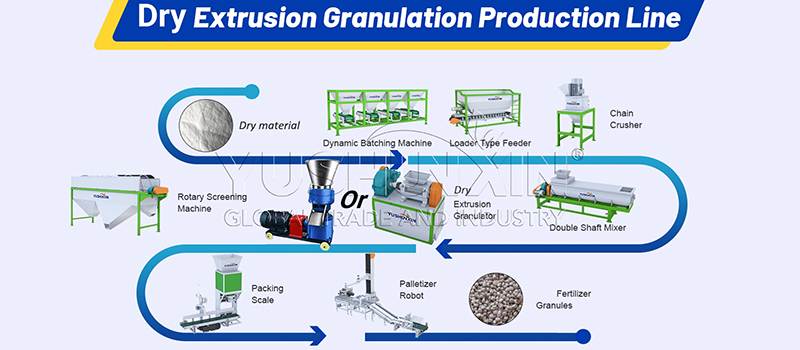

Dry fertilizer granulation process

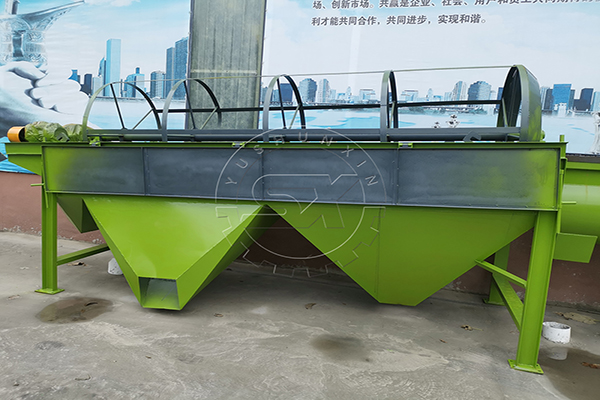

The first option is a dry granulation line. It consists of a groove-type compost turner, chicken dung compost crusher, double roller granulator, rotary screening machine, and automatic packaging equipment. This solution is compact, energy-saving, and requires no drying process. So, it is the most cost-effective choice to use chicken dung as organic fertilizer.

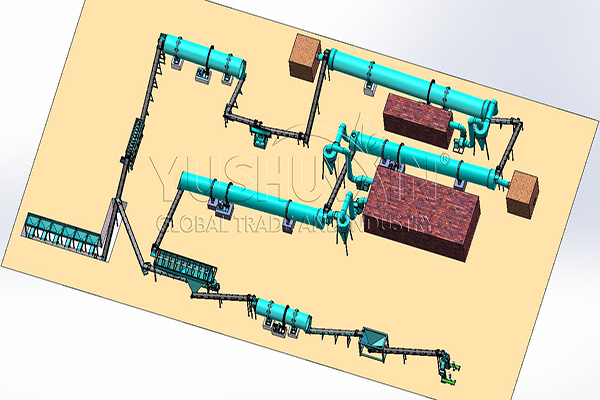

Wet fertilizer granulation plant

The second option uses wet granulation technology, equipped with chicken compost turner, disc granulator, drying and cooling system, drum screener, and packing system. This system offers higher output flexibility and better granule shaping but involves higher energy consumption and equipment cost.

Final, the customer in Nigeria choose the dry chicken poop fertilizer production line because of limited budgets and low moisture chicken manure.

Overseas Branches Empower YUSHUNXIN’s Fertilizer Machine Services in Nigeria

Within 30 to 45 working days, the entire chicken manure fertilizer production line was successfully delivered to the client’s site in Nigeria. With the help of YUSHUNXIN’s Nigerian overseas office, our local engineers provided on-site guidance for installation and commissioning. Now, the chicken dung fertilizer factory is running smoothly. In addition to our Nigerian branch, we also have established overseas offices in the US, Indonesia, and Russia, allowing us to respond quickly to clients across different regions.

Content

- I requisiti dei clienti nigeriani per la linea di produzione di fertilizzanti per letame di pollo?

- Granulazione a secco o ad umido: SX fornisce soluzioni fertilizzanti per sterco di pollo in Nigeria

- Quali attrezzature vengono utilizzate nell'impianto di produzione di fertilizzanti per letame di pollo in Nigeria?

- Le filiali estere potenziano i servizi di macchine per fertilizzanti di YUSHUNXIN in Nigeria