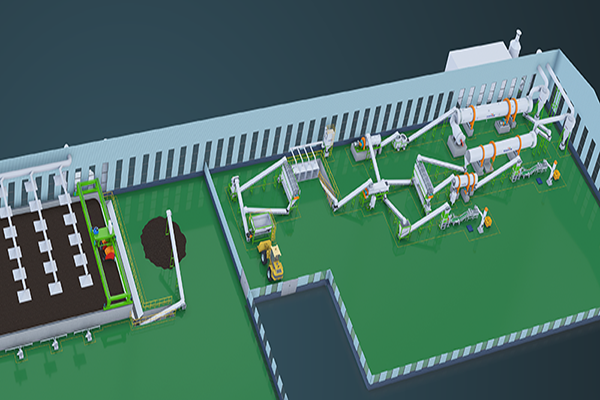

Managing tons of chicken manure daily can be overwhelming. Odor, pollution risks, and labor costs all pile up fast—especially on large poultry farms. SX offers a proven solution: a fully integrated 20TPH chicken manure fertilizer production line, engineered for high output and reliable performance. From composting and crushing to mixing, granulating, drying, and packing, every step is automated for speed and precision.The system reduces manual handling, shortens processing time, and delivers market-ready organic fertilizer with stable quality.

How Much Does a 20TPH Chicken Manure Fertilizer Production Line Cost?

The cost of a 20 tons per hour chicken manure fertilizer production line depends on your specific equipment configuration, plant layout, and degree of automation. On average, a complete set ranges from $400,000 to $500,000. The key factors influencing price include whether you choose a powdered or granular chicken dung fertilizer production line. For granular production, you may need more fertilizer production machines. The basic fertilizer plant consists of: a compost turner, crusher, mixer, granulator, dryer, cooler, screening machine, and bagging system. YUSHUNXIN can customize fertilizer production solutions to match your budget and output goals. Feel free to contact us!

Which Machines Are Best for a 20TPH Chicken Manure Fertilizer Plant?

The 20 tons/hour chicken manure fertilizer production line uses highly automated machinery to convert chicken manure raw materials. And it often produces high-quality granular organic fertilizers through a series of fine processing processes. It not only efficiently handles a large amount of chicken manure, reducing environmental pollution, but also realizes the recycling of resources, turning it into money. If you want to produce a large amount of chicken poop fertilizer, then the following machines is for your reference.

Making chicken manure compost

Manure Dewatering Machine

Wet chicken manure is difficult to handle and process. A manure dewatering machine can reduce the moisture content of the chicken dung to about 20-30%. That is helpful to make compost. This step is crucial for efficient composting and further processing. You can choose a SXTS-230 solid liquid separator.

Chicken Manure composter

Composting is a biological process that involves the decomposition of organic materials by microorganisms under controlled conditions. To process large volumes of chicken waste efficiently, you can use windrow compost turners for aerobic fermentation in long rows. Also you can use a wheel type compost turner, which can control temperature, moisture, and aeration more precisely. These 2 compost turners can compost raw materials more then 20t per hour, which can help you finish your composting task.

Granulation Process

After composting, chicken manure often contains clumps and oversized particles. To prepare it for granulation, you need a reliable crushing step. A high-output pulverizer breaks down these materials quickly and evenly, improving the consistency of your compost. For this process, a new type vertical crusher or a chain crushing machine works well. Both options feature high efficiency, fast crushing speed, and strong adaptability to organic materials. Choosing the right crusher helps you produce finer chicken dung powder, which leads to higher granulation quality and better fertilizer performance.

For large-scale chicken manure fertilizer production, we highly recommend a horizontal mixer or double-shaft mixer for the customer. These machines provide fast, uniform mixing of compost with added nutrients like nitrogen, phosphorus, or potassium. The horizontal mixer features simple structure and easy operation, while the double-shaft mixer offers stronger blending power and better moisture handling. All are made of 304 stainless steel, which is highly corrosion-resistant.

For 20t/h chicken manure fertilizer production, a rotary drum granulator is the ideal choice. It handles large volumes efficiently, forming granules through continuous rotation and mild pressure. This method ensures high output and stable granulation. To improve granule uniformity or boost capacity during peak demand, you can also add a disc pelletizer after drum granulation. This flexible setup helps you achieve better shaping and consistent product quality. Or you can consult other chicken manure pellets making machine.

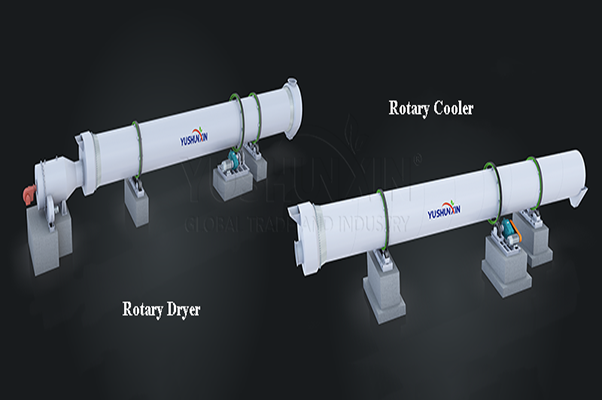

After granulation, the fertilizer pellets are still too moist and hot for storage or application. A rotary drum dryer removes excess moisture by circulating hot air through the tumbling granules. Then, a cooling machine quickly lowers the temperature to prevent caking and preserve granule quality during storage. This drying and cooling process is essential for producing stable, easy-to-store chicken poop fertilizer products.

Automatic Fertilizer Packaging Machine

YUSHUNXIN recommends a double-bucket automatic bagging machine for the 20 TPH chicken manure fertilizer plant. It accurately fills and seals 25kg or 50kg bags using precision weighing and control systems. This ensures consistent product weight and reduces error. To further streamline packaging, you can add an automatic sewing machine and palletizer for fast bag sealing and stacking. This complete setup improves packing speed and gets your fertilizer ready for transport or sale efficiently.

How Long Does It Take to Turn Chicken Manure into Organic Fertilizer?

Typically, it takes 15 to 25 days to convert raw chicken manure into mature compost, depending on environmental conditions and the composting method. Using a suitable compost turner shortens fermentation time by improving oxygen supply and temperature control. Once composted, crushing, mixing, granulating, drying, and screening can take another 1–3 days to complete. Therefore, you can expect the whole chicken poop fertilizer manufacturing process to take about 20–30 days for a full cycle. With a 20TPH system running continuously, you can process thousands of tons monthly. Our complete lines are designed for efficiency, helping you maximize output and fertilizer quality.

Top Benefits of Investing in a 20TPH Chicken Manure Fertilizer Production Line

Too much chicken manure can cause pollution and storage problems. A 20TPH fertilizer production line helps you process waste quickly. It turns raw manure into valuable organic fertilizer. This line includes composting, crushing, mixing, granulating, drying, and packing.

SX delivers not just machines—but complete, profitable fertilizer production solutions. Welcome to consult us!

Content

- How Much Does a 20TPH Chicken Manure Fertilizer Production Line Cost?

- Which Machines Are Best for a 20TPH Chicken Manure Fertilizer Plant?

- How Long Does It Take to Turn Chicken Manure into Organic Fertilizer?

- Top Benefits of Investing in a 20TPH Chicken Manure Fertilizer Production Line

- Why Do Poultry Farmers Choose SX’s 20TPH Chicken Waste Fertilizer Line?