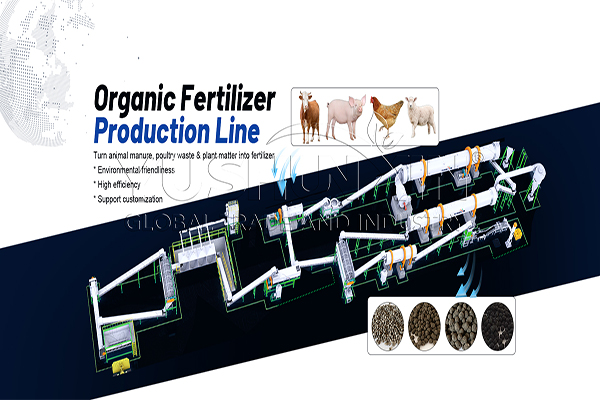

In today’s agricultural development, small scale fertilizer production line becomes the choice of agricultural producers. Because small scale fertilizer production lines are high efficiency and environmental protection. Through a series processes, small size fertilizer production line can produce high quality fertilizer with rich nutrients by converting organic waste into organic fertilizer. The following is the information about fertilizer production line at small scale.

Key Preparations Before Starting a Small-Scale Fertilizer Production Business

Before investing in a small-scale fertilizer production business, most fertilizer manufacturers should focus on three practical questions: raw materials collection, equipment selection, and plant layout. Because these factors directly affect project cost, operating stability, and future expansion.

Choose Raw Materials with Strong Adaptability

For small fertilizer production projects, it is best to start with easy-to-source and flexible raw materials. Common options include: Livestock manure: cow dung, chicken manure, pig manure, goat manure. Agricultural waste: straw, sawdust, maize stalks, soybean residues. Organic and industrial waste: biogas residue, sludge, sugar waste, mushroom residue. These raw materials adapt well to different fertilizer production processes. So it is suitable for first-time fertilizer manufacturers.

Select Equipment Based on Your Production Needs

You should select the small scale fertilizer production equipment according to your budget, raw material, and final product. Different fertilizer types require different equipment combinations. For example, powdered fertilizer lines, granulation lines, and BB fertilizer systems use completely different process designs. If you are unsure which machines you need, YUSHUNXIN can customize suitable fertilizer production machine.

Design a Cost-Effective Fertilizer Plant Layout

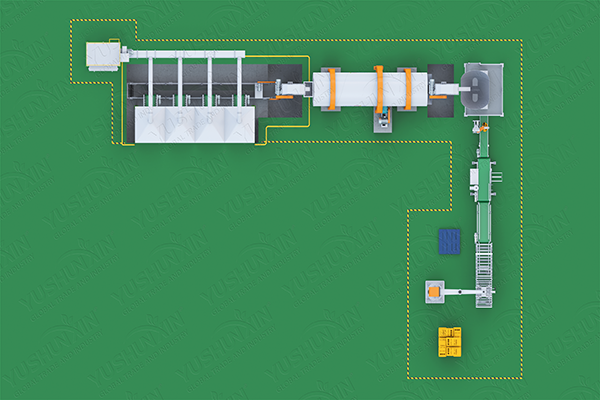

Plant layout is another common concern for fertilizer beginners. A small-scale 1–5 T/H fertilizer production line usually requires about 1,000 m² of land. This area is enough for raw material storage, processing zones, finished fertilizer storage, and basic material handling. To reduce land and construction costs, we recommend locating the fertilizer plant outside urban areas and close to raw material sources. This layout helps lower transportation expenses and improves overall production efficiency.

2 main small scale fertilizer production line for sale in YUSHUNXIN

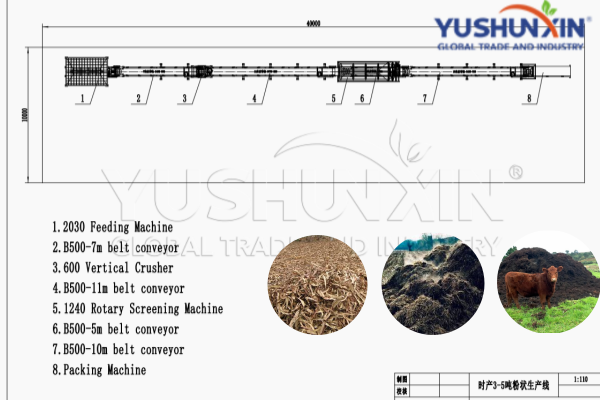

Choosing suitable equipment is essential for running a small-scale fertilizer factory. Different fertilizer forms require different fertilizer production machines. Below are the typical equipment configurations for small-scale fertilizer plants based on product type.

1–5 T/H Granular Fertilizer Production Line

Based on the powdered fertilizer processing system, a 1–5 T/H granular fertilizer production line adds granulation and drying equipment to produce uniform fertilizer pellets with better appearance and higher market value.

Fertilizer Granulation Equipment for Making Pellets

Granulation is the core step in granular fertilizer production. According to the investment budget, wet granulation and dry granulation solutions are both available for small-scale fertilizer plants.

Wet granulation is suitable for organic fertilizer and other materials with relatively high moisture content. The SXYZ-3000 disc granulator and SXZGZ-1560 drum pelletizer are typical wet granulation machines, capable of producing up to 5 tons of round fertilizer granules per hour. To improve durability and service life, YUSHUNXIN applies corrosion-resistant designs to key components in contact with raw materials. Such as fiberglass granulation discs and Q235B carbon steel granulation drums.

Dry granulation does not require drying or binder addition, which helps significantly reduce investment cost. In small-scale fertilizer granulation plants, flat die granulators and roller extrusion granulators are commonly used. These machines convert powdered materials directly into fertilizer pellets through mechanical extrusion, making them suitable for low-moisture raw materials.

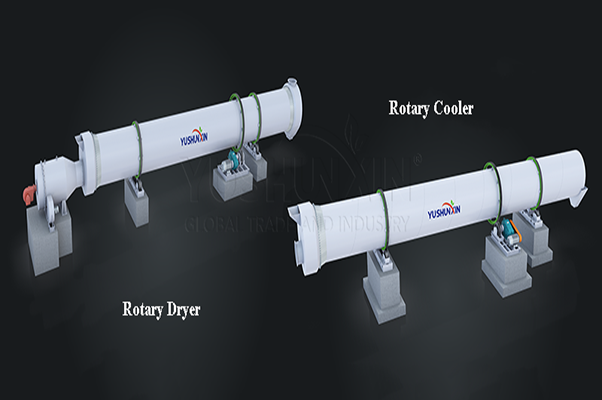

Drum Dryer and Cooler for Moisture Control

After granulation, fertilizer pellets usually contain excess moisture. The rotary drum dryer reduces moisture to a safe level for storage, while the drum cooler lowers pellet temperature and enhances granule strength. Together, these machines help prevent caking and improve the overall quality of finished fertilizer products.

Optional Equipment for Higher-Quality Fertilizer Granules

If your budget allows, you can add the following machines to further improve pellet appearance and performance:

How much does a small size fertilizer production line cost?

The cost of a small-size fertilizer production line mainly depends on the final product form—powdered or granular fertilizer.

Small Scale BB Fertilizer Production Line for Sale – Low Cost, Fast Return

Can you provide a more economical way to start a small fertilizer business? Yes. The BB fertilizer production line is one of the most cost-effective options for small investors. This system uses a simple production process: batching, mixing, and packaging. You do not need granulation, drying, or cooling machines. This helps you reduce both initial investment and operating cost.

When you start BB fertilizer production, you use finished fertilizer granules as raw materials, such as urea, DAP, MAP, potassium chloride, or organic fertilizer pellets. Then, a standard BB fertilizer production line includes:

- Automatic or semi-automatic batching system

- BB fertilizer mixer to ensure uniform mixing of different granules

- Conveying system for material transfer

- Bagging machine for 25 kg or 50 kg fertilizer packaging

Where can you purchase a small size fertilizer production line?

When you are considering buying a small fertilizer production line, choosing YUSHUNXIN is a good choice for you.

In a word, choosing us to purchasing a small fertilizer processing plant is a wise choice for you. Looking forward to your inquiry.

Content

- Key Preparations Before Starting a Small-Scale Fertilizer Production Business

- 2 main small scale fertilizer production line for sale in YUSHUNXIN

- How much does a small size fertilizer production line cost?

- Small Scale Powder Fertilizer Production Line cost.

- Small Scale fertilizer granulation plant cost.

- Small Scale BB Fertilizer Production Line for Sale – Low Cost, Fast Return