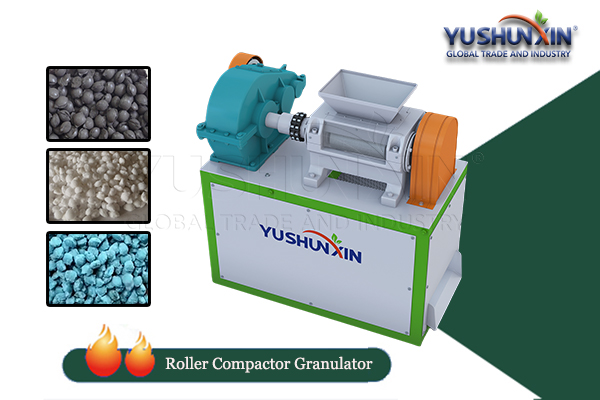

If you’re looking for affordable fertilizer granulation equipment, we recommend a roller granulator. First, it uses a dry granulation process to produce fertilizer granules, which reduces fertilizer drying and cooling costs. Second, the YUSHUNXIN roller compactor granulator offers a competitive price. Therefore, a roller granulator is the best choice for producing granular fertilizers at a low cost.

What’s the price of roller compactor granulator?

When you plan to make fertilizer granules economically, the double roller extrusion machine is the best choice. In general, the price of a roller press granulator is only $3,000~$12,000. For one thing, it has a capacity for small scale fertilizer production, 1-4t/h. For another, adopts dry granulation method, it can granulate powder fertilizer without drying. So, reduce the expense on fertilizer dryer purchasing and produce granular fertilizer at a lower investment.

The roller compactor granulator is very economical. Its cost is different according to model, capacity, and so on. The greater the production capacity, the higher the cost. If you want to produce other shapes of fertilizer, you just need to change roller sheet. At the same time, you can also use it to produce 3-10mm fertilizer granules. What’s more, the rotating roller is made of boiler steel, which is wear-resistant and corrosion-resistant. And you just need to replace the mold once a year that can save you a lot money. Therefore, it’s a kind of economic granulation machine suitable for small scale fertilizer production line.

| Model | Power(kw) | Granule Diameter(mm) | Roller Sheet Size(mm) | Dimensions(mm) |

|---|---|---|---|---|

| SXDG-1T | 15 | 3-10 | 150*220 | 1450*800*1450 |

| SXDG-1.5T | 18.5 | 3-10 | 150*300 | 1450*850*1500 |

| SXDG-2T | 22 | 3-10 | 185*300 |

1630*850*1650 |

What’s the working principle of a roller press granulator machine?

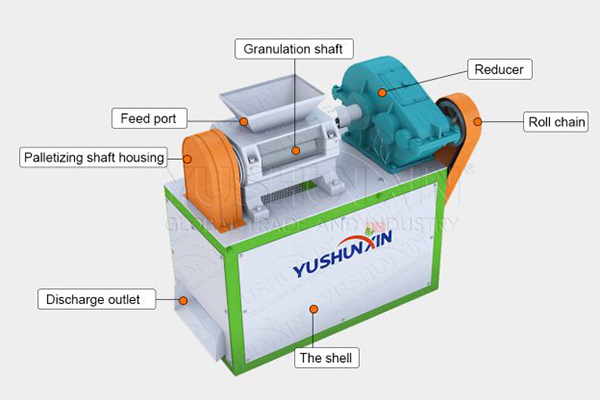

How does the roller compactor granulator work to make fertilizer granules? The machine adopts dry granulation method, which mainly relies mechanical extrusion force to press material powder into flat ball fertilizer pellets. It wil feed powder to the two counter-rotating rollers, which have specific grooves or shapes. So, when pass the gap between the rollers, the compost or chemical powder will form into desired pellet sizes. This press fertilizer granulation machine is advantageous because it doesn’t require additional binders (like water )or high temperatures, preserving the nutrient content of the compost.

What materials is suitable for roller compact granulator?

Because different fertilizer granulation machine has different requirements for materials.It’s necessary for you to know about what materials is suitable for this kind of machine when you choosing a roller compact granulator.

Double roller granulator is a dry granulation machine. It requires the feed materials moisture is between 5%-10%. Many fertilizer manufacturers choose use it in compound fertilizer production line. For example, the raw materials that contain nitrogen, phosphorus and potassium. You can use a roller press granulator for NPK compound fertilizer pelletizing and snow removal pelletizing. Because the extruder compactor has a high anti-corrosion resistance.

Top 3 Advantages of double roller granulator for fertilizer making

Roller extrusion granulator popular with fertilizer making manufacturers because of features as follows:

The pelletizing process of roller extrusion granulator is quickly and continuous. What’s more, it is helpful to improve fertilizr production efficiency. And the granulation rate of roller compactor granulator is more than 95% that can produce high quality fertilizers. The hardness of granules made from double roller granulator is 15-20N. In addition, through mechanical extrusion, roller extrusion granulator can produce fertilizer pellets of consistent size and shape.

Compared with the traditional wet pelletizing process, the roll extrusion pelletizing process doesn’t require the addition of water or heating, therefore the double roller extrusion granulator can significantly reduce energy consumption. YUSHUNXIN’s double roller extrusion granulator is electrically controlled and has low energy consumption. And there is no need to use water and solvents during granulation. Because it can reduce waste water and exhaust emissions as well as benefit to environmental protection. In addition, the whole granulation process is completed in a closed state that can reduce the dust flying and improve fertilizer production environment.

In addition to the benefit mentioned, the double roller compactor granulator is also easy to operate. Therefore, the double roller extrusion granulator is an economic granulation machine for you. You can contact YUSHUNXIN to customize your machines.

Can you provide us with the complete double roller granulation line?

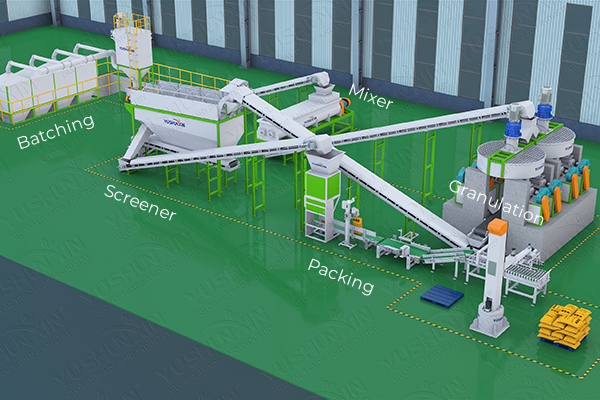

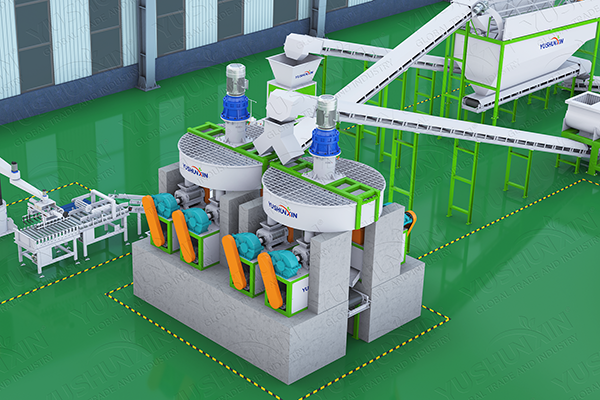

Ofcourse, in additional to a single roller compactor granulating machine, YUSHUNXIN offers a cost-effective fertilizer production line built around our roller extrusion granulator. The meticulously designed line ensures seamless integration from precise raw material conveyance to granule packaging. The price of this fertilizer production line is generally between $10,000 and $20,000. However, its configuration is not fixed. You can consult us to get the most suitable double-roll extrusion granulation production line at a favorable price.

How to improve the economic benefits of roller granulator in fertilizer manufacturing?

Besides that, you can improve your economic efficiency from other aspects like energy management, waste management and product development. All of these should on the basis of ensuring the quality of fertilizer.

In addition to the double-roll extrusion granulator, YUSHUNXIN can also provide you with wet granulation machines at the most favorable price for fertilizer pellets making. Such as disc pelletizer, drum granule making machine. Feel free to contact us!

Content

- What’s the price of roller compactor granulator?

- What’s the working principle of a roller press granulator machine?

- What materials is suitable for roller compact granulator?

- Գագաթ 3 Advantages of double roller granulator for fertilizer making

- Can you provide us with the complete double roller granulation line?

- How to improve the economic benefits of roller granulator in fertilizer manufacturing?