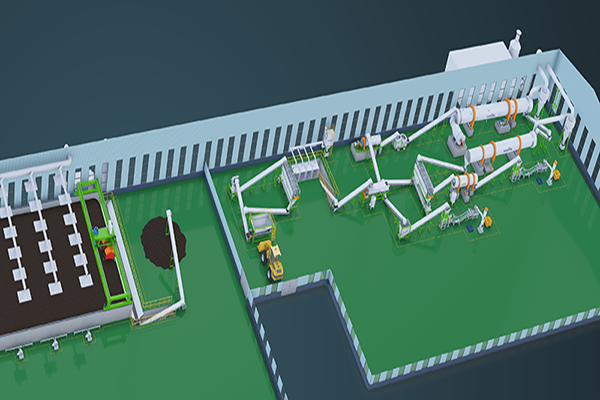

Organic fertilizer granulator plant, as an indispensable equipment for modern agriculture, has attracted wide attention. It uses advanced technology to convert organic waste into fertilizer granules that are easy to store and use. And using organic fertilizer granulation plant can reduce environmental pollution and improves soil fertility and crop yields. Next, we will introduce the working principle and application of organic fertilizer granulator.

What’s the price of organic fertilizer granulation plant?

The cost of building an organic fertilizer granulation plant varies widely—ranging from $110,000 to $550,000. It depends on your production scale, automation level, raw materials, and configuration.

If you aim for a medium-to-large scale production (5–10+ TPH), with drying, cooling, screening, and dust control systems, the cost may go up to $190,000–$400,000. You can choose pan, rotary drum, or double roller granulators based on your material type and market demand.

Additionally, fermentation methods of you choose and post-treatment steps (like coating or polishing) will also affect the price. The information is only for reference. When you deciding to purchase an organic fertilizer granulator machine, you should also consider other factors like your budget, additional functions and services.

What’s the application of organic fertilizer granulation plant?

An organic fertilizer granulation plant is designed to process a wide range of organic raw materials and convert them into stable, easy-to-handle fertilizer granules. Its flexibility makes it suitable for agricultural, livestock, and municipal waste recycling projects.

- Firstly, an organic fertilizer granulation plant can process agricultural residues, including crop straw, corn stalks, rice husks, leaves, grass clippings, and other plant-based biomass. After crushing, composting, and granulation, these materials can be transformed into marketable organic fertilizer products.

- Secondly, the system is widely used for livestock and poultry manure granulation, such as cow dung, chicken manure, pig manure, and sheep manure. By mixing animal manure with agricultural waste or fermentation additives, the granulation process helps reduce odors, suppress harmful microorganisms, and significantly improve fertilizer value.

- In addition, an organic fertilizer granulation plant can handle urban organic waste and landscaping residues, including garden waste and composted municipal organics, supporting sustainable waste recycling and organic fertilizer production.

- Organic fertilizer granulator has a wide range of applications, therefore, you can use it to granulate different raw materials, which is helpful to improve the utilization rate of the granulator. And at the same time, it can also help you reduce unnecessary expenses.

Why you choose SX to buy an economic organic fertilizer granulator plant?

SX is a professional organic fertilizer granulator manufacturer with long-term experience in fertilizer equipment design and production. We understand different granulation requirements, raw materials, and production goals. If you face any granulation issues, our engineers provide clear technical solutions quickly and efficiently.

As a direct manufacturer with our own factory, SX offers granulators at competitive prices without unnecessary middle costs. This helps customers control the total organic fertilizer plant cost while maintaining reliable equipment quality.

Our in-house R&D and engineering team designs granulation systems based on your local energy conditions, agricultural regulations, and target fertilizer formulas. Each pelletizer focuses on stable output, uniform granule quality, and low energy consumption.

SX also provides practical after-sales support, including installation guidance and operation training. All key components use wear-resistant and corrosion-resistant materials, which ensures long service life and low maintenance cost. Our granulators are easy to operate and suitable for long-term continuous fertilizer production.

How long does it cost of granulating organic fertilizer?

The granulation process of organic fertilizer generally includes the steps of composting and fermentation, crushing, mixing, granulation, drying and cooling, and packaging. It takes only 15-20 days to ferment using a composting machine. And the granulation time will be different because of the different granulation methods, granulation requirements and granulator function, etc. Generally, the granulator can complete a batch of organic fertilizer granulation within 10 minutes. In short, using our company’s granulator can help you granulate quickly and efficiently. Meanwhile, choosing the right granulator is also helpful to improve the quality of fertilizer granules.