In modern agricultural production, rational use of resources is the key to improving efficiency and environmental protection. Manure dewatering machine plays a vital role in this process. And you can use this kind of equipment to deal with large amounts of materials that containing water, not only effectively removing excess water, but also ensuring the cohesion and stability of the fertilizer, creating conditions for subsequent processing and transportation.

4 Hot selling manure dehydrators for manure fertilizer production in SX

As a key tool in fertilizer production, manure dewatering machine plays an important role. The manure dehydrating machines selling in our company have the advantage of high efficiency and fast dehydration. At present, we have 2 types of manure dehydrators for sale. The following is the information of solid-liquid separator machine and inclined screen separator.

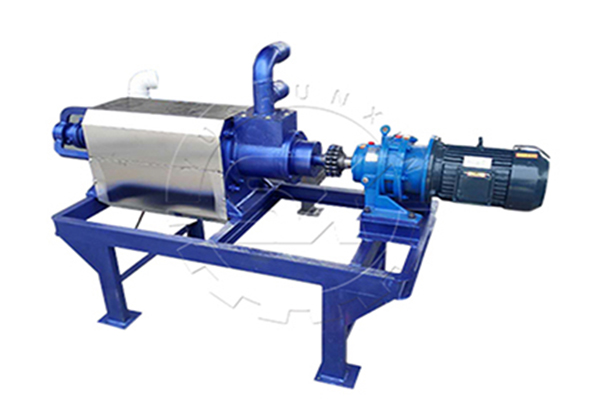

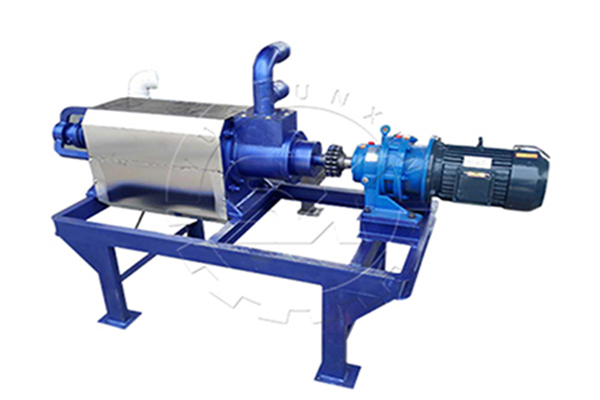

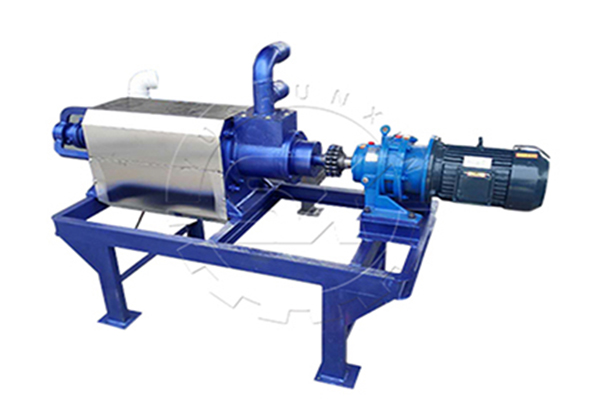

Solid-Liquid Separation Machine–High Dewatering Efficiency

Solid-liquid dewatering machine separates the solids and liquids in the materials through physical extrusion and sieving action, realizing waste reduction and resource utilization. It can separate solid and liquid quickly through screw extrusion. You can also use a manure dewatering machine after organic fertilizer granulation plant. It’s suitable for dewatering materials with the humidity of 50%~90% and the moisture content of the dewatered materials is in the range of 30%~40%, which can dehydrate 10-20m3 materials per hour. It only costs you $1,000~$6,000.

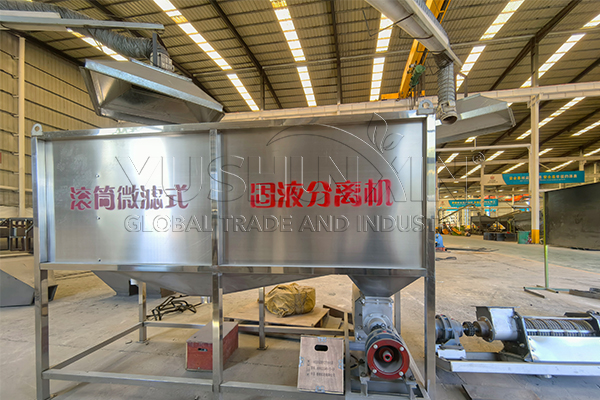

Inclined Screen Separator

Inclined screen dewatering machine relies on the gravity and permeability of the material on the inclined screen mesh. As well as the pressure generated by the weight and movement of the material itself, so that the liquid is discharged through the holes of the screen, while the solids move along the screen mesh for dewatering and separation. It can dehydrate 15-40m3 materials in an hour. And it has a wide range of application that is suitable for dehydrating materials with 90% moisture content. And it has a high efficiency of dewatering of 95%. therefore, if you have high demand of dewatering, then the inclined screen separator suits you best.

Multi-Plate Screw Press – Clean Separation & Strong Anti-Clogging

The multi-plate screw press uses a screw and moving plates to squeeze water from raw manure. Its self-cleaning plate structure prevents clogging and ensures stable operation. It can handle materials with 60%–98% moisture, especially manure mixed with sand, bedding, or fine fibers. The machine processes 8–25 m³/h depending on model size. And the final solid moisture rate remains around 30%–45%. Its biggest advantages are automatic cleaning, low washing-water demand, and long running cycles. The multi-plate screw press costs $3,000–$12,000. So it is suitable for farms that need continuous 24h dewatering.

Rotary Drum Dewatering Machine – Stable Output for Large Volumes

The rotary drum separator relies on a rotating perforated drum and internal scraper blades. As raw manure enters the drum, rotation spreads the material evenly. It works well with manure slurries containing 70%–95% moisture. The rotary drum separation equipment can handle 20–60 m³/h, ideal for large dairy farms, pig farms, and biogas plants. After separation, solids usually reach 35%–45% moisture, depending on the raw manure. Moreover, this equipment offers strong durability, easy maintenance, and high-capacity operation with fewer blockages. The price ranges from $4,000–$10,000, depending on drum size and power configuration.

What Raw Materials Can Be Processed With a Manure Dewatering Machine?

A manure dewatering machine handles a wide range of organic waste from farms, biogas plants, and fertilizer production lines. Different raw materials show different fiber levels, moisture content, and viscosity, but they all can be efficiently separated after matching the right type of separator.

How does the manure dewatering machine work?

Why do you need a dewatering machine for poultry and animal poop management?

In cow dung fertilizer production line, using a dehydrating machine is very important for the substance production. And using a dewatering machine can benefit you a lot for fertilizer production.

How to maintain the manure dewatering machine for long use?

It’s very important for you to maintain the manure dewatering machine daily for longer use. Firstly, before and after each use, you need to check the parts are intact and clean the machine to prevent clogging. And regularly lubricate the moving parts, replace worn out wearing parts, and keep the electrical parts dry. Operators also need to familiarize themselves with the operation of the equipment and avoid overloading. When encountering complicated problems, contact a professional in time. Doing so can prolong the life of the machine and keep it operating efficiently.

How to improve the utilization of livestock and poultry manure with a manure dewatering machine?

- If you are struggling to deal with large quantities of manure, we have the perfect solution for you.

- It is the most common method of converting manure into organic fertilizer by using a

windrow compost turner. In the process of composting, you should control the temperature, moisture content and oxygen supply to promote the activity of microorganisms. After fermentation, the organic fertilizer not only helps to promote the soil structure, but also provide essential nutrient with crops. In the meanwhile, it’s also an environmentally friendly way to recycle and reduce the use of chemical fertilizer. - In the real practice, it needs the steps of pretreating, dehydrating and disposal after dehydration to achieve rational use of manure. The comprehensive measure can not only improve the use of poultry and livestock manure, but also provide an environmental friendly and sustainable development solution to agriculture development.

Content

- 4 Warmverkoper mis dehydrators vir die produksie van miskunsmis in SX

- Watter grondstowwe kan met 'n misontwateringsmasjien verwerk word?

- Hoe werk die misontplaatsmasjien?

- Waarom het u 'n ontwateringsmasjien nodig vir pluimvee en diere -poepbestuur?

- Hoe om die misontplantingsmasjien vir lang gebruik te onderhou?