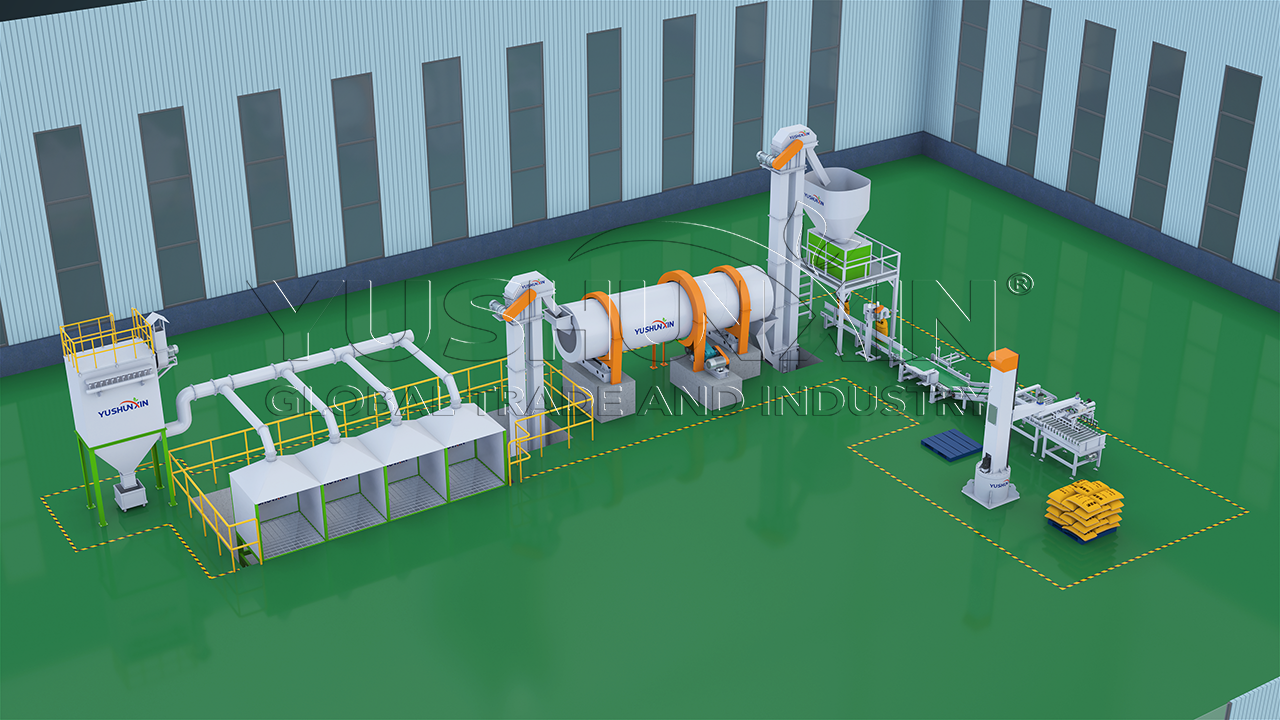

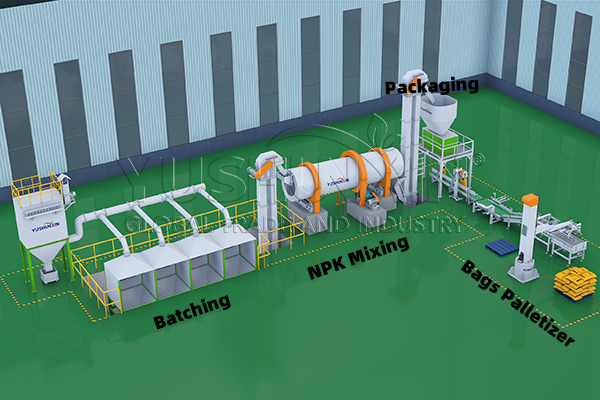

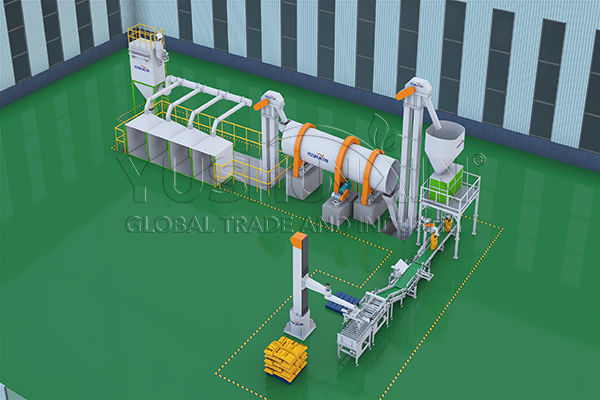

A bulk blending fertilizer line is a highly efficient system for producing customized NPK fertilizer mixtures through batching, mixing, and packing processes. Unlike compound fertilizer production, this line focuses on proportioning and blending different granular fertilizers according to specific nutrient formulas. With low investment, short processing time, and easy operation, it has become an ideal choice for fertilizer suppliers. Get your bulk blending fertilizer production equipment today.

How to Start a Bulk Blending Fertilizer Production Line: Step-by-Step Guide

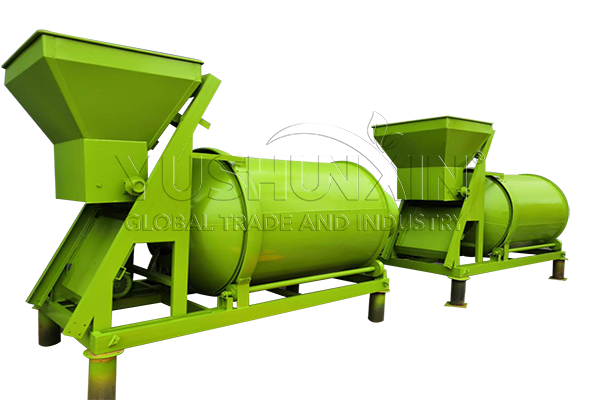

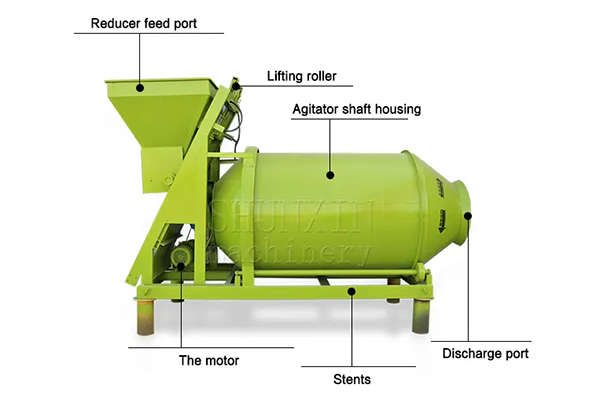

After dosing the raw materials, the belt conveyor will transport the fertilizer into a BB fertilizer mixer for uniform blending. The blending process can ensure even distribution of fertilizers. And that is very important to keep the homogeneity of the BB fertilizer.

After mixing, the final step in BB fertilizer production is packaging. You can use a fertilizer packing line to divide the fertilizer into equal portions. It makes it easier to store and transport.

Bulk Blending Fertilizer Production Line Price: How Much Does It Cost in 2025?

The price of a bulk blending fertilizer production line is much lower than that of other fertilizer production systems, such as compound fertilizer production line, or organic fertilizer production, bio fertilizer production line. This is because BB fertilizer production is easy to operate and requires less processing time.

A BB fertilizer factory usually costs around $5,000 to $300,000, which is for your reference only. When considering purchasing a bulk blending fertilizer production line, you should take several factors into account, such as the equipment functions, degree of automation, production capacity, and other specific requirements. The final price may vary depending on your actual needs.

Essential Equipment for Bulk Blending Fertilizer Manufacturing

Because of the simple process of bulk blending fertilizer manufacturing, fertilizer suppliers only need three main types of equipment: a batching machine, a BB fertilizer mixing machine, and fertilizer packaging scales. Besides, YUSHUNXIN can customize these machines free of charge according to your specific production requirements.

How to Make Different BB Fertilizers with One Bulk Blending Fertilizer Line?

Many fertilizer suppliers want to produce different BB fertilizer formulas, such as 20-20-20, 15-15-15, or other customized ratios. In practice, this is not complicated. A flexible and accurate fertilizer batching machine is the key. Because the BB fertilizer manufacturing relies on physical blending. Its raw materials keep their original particle shape. Therefore, the final nutrient ratio depends entirely on precise weighing and proportion control.

-

BB Fertilizer Batching Machine – The Key Equipment in a Bulk Blending Fertilizer Line

BB Fertilizer Batching Machine – The Key Equipment in a Bulk Blending Fertilizer Line

Operators can quickly switch formulas such as 20-20-20, 15-15-15, or 10-26-26 through the control system. This design reduces downtime, improves production efficiency, and minimizes manual errors.

What Raw Materials Are Used in Bulk Blending Fertilizer Production?

Bulk blending fertilizer production selects granular raw materials based on their N, P, and K nutrient content. You can produce different formulas, such as 20-20-20 or 15-15-15 by adjusting the proportion of each nutrient source.

Top 2 Benefits of Investing in a Bulk Blending Fertilizer Production Line

With a relatively low investment, a bulk blending fertilizer making line offers a practical solution for fertilizer producers who want high output, low cost, and quick market entry. The following benefits explain why more investors choose bulk blending systems.

Content

- How to Start a Bulk Blending Fertilizer Production Line: Step-by-Step Guide

- Bulk Blending Fertilizer Production Line Price: How Much Does It Cost in 2025?

- Essential Equipment for Bulk Blending Fertilizer Manufacturing

- How to Make Different BB Fertilizers with One Bulk Blending Fertilizer Line?

- What Raw Materials Are Used in Bulk Blending Fertilizer Production?

- Arriba 2 Benefits of Investing in a Bulk Blending Fertilizer Production Line