On April 17, 2025, we received an inquiry from a customer in Mexico who planned to set up a small cat litter factory using sodium bentonite as the main raw material. We provided a complete set of cat litter production equipment tailored to his needs. According to his feedback, the line is running smoothly with stable performance. If you’re planning a similar kitty litter production project, feel free to contact us—we’re here to help!

What Are the Basic Requirements for the Cat Litter Production Line?

The client from Mexico took advantage of market opportunities to purchase sodium bentonite raw materials from China, the United States, and Spain. They want to start a small scale bentonite series product construction project. The following are the basic needs of customers:

What Are the Basic Requirements for the Cat Litter Production Line?

Dynamic Batching Machine

To ensure precise formula control, we recommend using a dynamic batching machine to prepare raw materials. This system automates the weighing and feeding process, significantly reducing manual errors and improving overall batching efficiency.

Single-Shaft Mixing Machine

The single-shaft mixer is ideal for small-scale cat litter production. It blends bentonite powder and additives uniformly, creating a consistent base for granulation. Moreover, its simple structure, low energy consumption, and easy maintenance make it a cost-effective choice for the customer.

Pan Granulator

The disc pelletizer is the core equipment for shaping cat litter. It forms the blended material into round, uniform granules. By adjusting the angle and rotation speed of the pelletizing disc, customers can effectively produce 4mm cat litter pellets to meet market standards.

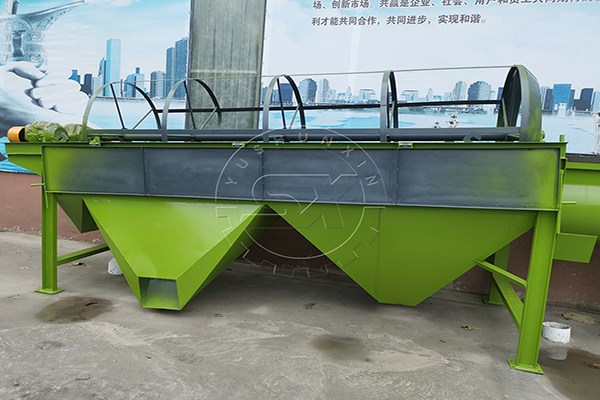

Screening Machine

To improve kitty litter uniformity, a drum screening machine removes fine powder and oversized particles. This ensures consistent granule size and a cleaner final appearance. Rejected particles are returned to the feeding system for reprocessing, reducing waste and improving output efficiency.

Dust Collection System

After understanding our Mexican client’s needs, we installed a pulse dust collector and an enclosed dustproof hood. This setup effectively reduces airborne dust and helps meet environmental protection standards during mixing and granulation.

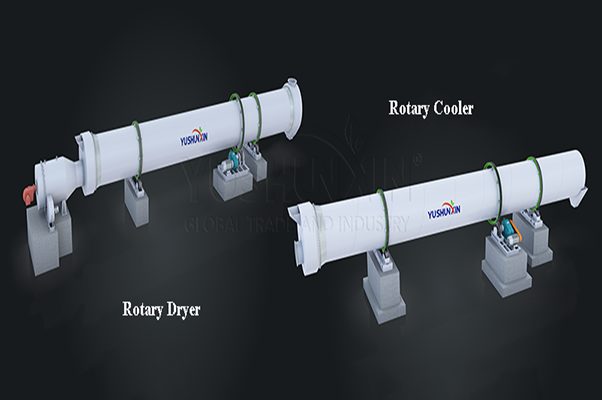

Drying and Cooling System

The granulated bentonite cat litter is dried using microwave drying equipment to remove excess moisture. Cooling follows to stabilize granule quality and reduce the risk of breakage during packaging and transport.

Single-Bucket Packaging Machine

YUSHUNXIN’s automatic packaging machine accurately weighs, fills, and seals 5kg, 10kg, or 20kg bags. It’s easy to operate and ideal for small-batch production. The final product is ready for direct sale or warehouse storage.

How to reduce dust in the cat litter manufacturing process?

For the Mexican customers, dust control is a critical issue in bentonite cat litter factory—particularly during mixing and granulation. For this, YUSHUNXIN’S staff recommends two effective solutions.

We’ve helped clients apply both solutions with great results—less mess, safer work conditions, and better machine performance. If you want to upgrade your current kitty litter line or plan a new one, let’s talk about how we can integrate these dust-control features into your setup.

When to Adjust Moisture in Bentonite Cat Litter Processing?

The best time to adjust moisture is in two key stages.

- First, add water to 8–10% during premixing to prepare materials for shaping.

- Then, during disc granulation, spray to reach 12–15%—this helps you control pellet size and strength more precisely.