In the field of pet cats care, high quality cat litter is very important. Because it can keep the home clean and provide a comfortable living environment for pets. Granulating cat litter is the key part in the process of producing cat litter. And it not only influences the absorption of cat litter, the ability of reduce odors, but also affects the environment properties of the product and the experience. Cat litter production line is becoming more efficient and environmentally friendly, providing more high-quality options for cat owners.

Top 2 hot selling cat litter manufacturing line in sx

Bentonite Cat Litter Production Line

Bentonite cat litter production involves several key steps. First, bentonite clay is mined and crushed using a jaw crusher. The crushed clay is then dried in a rotary dryer to reduce moisture content to less than 10%. A grinding mill processes the dried clay into a fine powder, which is then granulated into uniform particles using a disc granulator. The granules are screened to ensure size consistency and finally packaged using an automatic bagging machine. This line efficiently produces clumping cat litter known for its superior absorption and odor control properties.

Tofu Residue Cat Litter Production Plant

Tofu residue cat litter production starts with shredding the tofu byproduct using a high-speed shredder. The shredded material is dehydrated with a screw press to lower moisture levels from 80% to about 50%. It is then mixed with additives in a horizontal mixer. A pellet mill compresses the mixture into pellets, which are dried further in a conveyor belt dryer to achieve optimal moisture content. The pellets are screened for uniformity and packaged with an automatic packaging machine. This eco-friendly litter offers excellent absorption and biodegradability, catering to environmentally conscious consumers.

How do you produce cat litter?

With the development of the pet industry, the demand for cat sand products continues to grow. That promotes the innovation of cat litter technology and production process. The production of cat litter involves several parts, including raw materials’ selection, handing, mixing with additives, granulating and packaging. The following is the basic production process cat litter for your reference.

Core Machines in the Cat Litter Manufacturing Process

Based on the above steps, a standard cat litter production line includes several key machines.

YUSHUNXIN’s complete cat litter manufacturing equipment is available in stainless steel, with customizable throughput from 1–30 TPH. Welcome to consult !

What’s the price of cat litter production line?

The cost of a cat litter production line can vary widely depending on the production capacity, type of cat litter, and level of automation. Below is a general cost breakdown based on different production scales:

Small-Scale Cat Litter Production Line

Estimated cost: $20,000 – $100,000

This setup typically includes essential machines such as a mixing unit, granulator or pelletizer, dryer, and a basic packaging machine. It requires more manual labor, as automation is minimal. This option is ideal for startups or small factories looking for a cost-effective solution with lower investment risk.

Large scale production line for cat litter

$100,000~$500,000

This kind of kitty litter production line is more automatic than small one. This system is fully automated, integrating raw material feeding, granulation, drying, screening, and automatic bagging. It’s designed for high-volume and continuous production, significantly reducing the need for manual operations.

The price we mentioned just for your reference. When you consider buying some cat litter making machines or production line for cat line, please contact with us. We will provide you with the most suitable cat litter manufacturing plant.

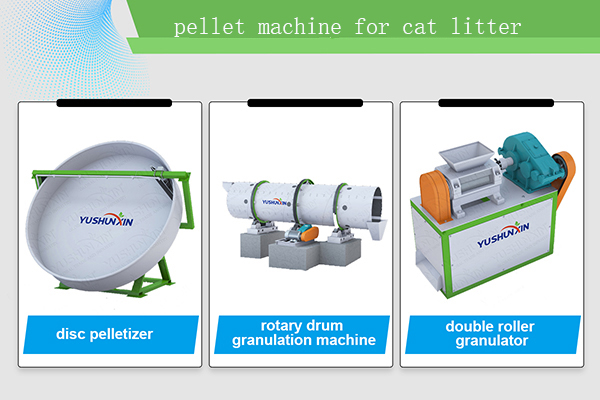

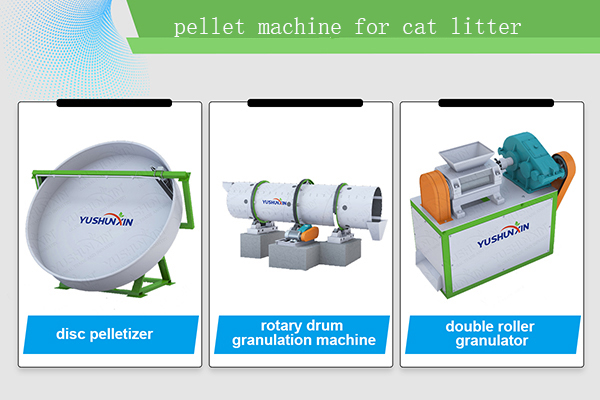

Top 3 cat litter granulating machine for sale in SX

With the rapid development of pet industry, the market for pet supplies, especially cat litter, is increasingly day by day. With the budget of $100,000, there are many cat litter granulating machines that for you to reference. Here, YUSHUNXIN are going to give a specific introduction about the best 3 cat litter granulating machine in our company. Hoping, it will help you select the cat litter granulating machine you want and bring you stable cat litter production interest and high market competitiveness.

Disc granulator for middle or small scale cat litter granulation machine at $1,000~$16,000

The pan granulating machine has a wide range of application in cat litter production because of its high efficiency and low cost. The working process of disc granulating is continuous that can improve the working efficiency greatly. What’s more, the disc granulating has a strong adaptation that you can produce different size of cat litter by adjusting the angel between ground and disc or adding water. What matters most is that the pan granulating machine can produce cat litter particles with more uniform shapes, which improves the appearance quality and market competitiveness of the cat litter. All in all, the disc granulating machine is suitable for small and middle cat litter production.

Rotary drum granulating machine for large scale cat litter granulating at $7,000~$70,000

A rotary drum granulating machine is suitable for large-scale cat litter production, which can produce cat litter at almost 30t/h. The rotary drum granulating machine has a high automatic degree that can produce cat litter efficiently and quickly. What’s more, the drum granulating machine can reduce material waste by knocking fertilizer off on the cleaning holes of the cylinder wall. In addition, the rotary drum granulator has strong corrosion that can produce cat litter longer. In a word, the drum granulator is suitable for those who have a large need for cat litter fertilizer production and with an enough budget.

Roll compactor granulator with dry granulation method for $3,000~$12,000

Adapting dry granulating method, double roller granulating machine can produce cat litter quickly. The fertilizer produced by the double roller granulating machine has a high hardness that is very suitable for storage and transportation. Because it uses dry granulating method, there is no need to dry and cool cat litter after granulating. That’s to say it can save much money and energy for you. In addition, the roller granulating machine can produce cat litter with the uniform size and shape. By changing the roller sheet, you can produce pellets in various shapes, such as pillow, strip, semicircle, etc.

How long does it cost to produce cat manure?

The production time of cat litter depends largely on the production method, scale, and automation level. For a typical medium-sized cat litter production line, the entire process—from raw material preparation to final packaging—takes about 4 to 6 hours per cycle. If you choose a fully automated cat litter making machine, the same process can be completed more quickly and consistently. Ultimately, the exact time varies based on the production layout, machine efficiency, and the operator’s technical expertise. If you’re aiming for higher output and faster turnaround, investing in automated kitty litter production systems is highly recommended.

Successful Case of Cat Litter Manufacturing Plant Built by YUSHUNXIN

We offer customized process designs and equipment configurations for cat litter manufacturers worldwide, tailored to factors such as raw material type and condition, desired product specifications, process requirements, and available plant space. Whether you need a complete cat litter production line or a specific processing system—such as granulation, drying, crushing, or packaging—we deliver efficient, high-performance solutions designed to meet your operational goals.

Sodium bentonite cat litter factory in Mexico

- Type Of Product: Sodium Bentonite Cat Litter Pellet. This Design Comes From One Of Our small scale Cat Litter granulation Line Projects In Mexico.

- Main Equipment Used: Dynamic batching machine Cat Litter Mixer, Bentonite Cat Litter Pellet Machine, Cat Litter Dryer Machine, Screening Equipment, Cooling Machine, Packaging Equipment, Converyors, Etc.

5 T/H cat litter machine for sale in Morocco

- Type Of Product: Cat Litter Pellet using nature bentonite ore. This Design we provided for customer in Morocco .

- Main Equipment Used: Raymond mill, Cat Litter mixing equipment, Drum granulator for cat litter pelletizing, Screening Equipment, Cat litter dry and cooling machine, Packaging Equipment, Dust collection system, Converyors, Etc.

7,000 TPY tofu kitty litter plant setup in Ecuador

- Type Of Product: Tofu kitty litter using tofu fiber, corn flour, starch, and guar gum. This plant we provided for customer in Ecuador .

- Main Equipment Used: Vertical type crusher, automatic batching machine, horizontal mixer, flat die granulator, drum screener, automatic packaging scale.

What other materials can cat litter production line produce?

The cat litter production line has a wide range of application that it can not only produce various types cat sand, but also produce other absorbent materials. For example, it can be used to make mattress materials, hygrometric materials and oil absorbent, perlite or vermiculite. This flexibility of the production line allows it to adapt to changing market demands. And it also provides enterprises with a wider range of product line expansion possibilities. In a word, using a cat litter production line produces a large amount materials that can improve your economic profits and increase the production line utilization rate.

Content

- A dalt 2 Línia de fabricació de sorra de gats de venda calenta a sx

- Com es produeix la sorra de gats?

- Màquines bàsiques en el procés de fabricació de escombraries per a gats

- Quin és el preu de la línia de producció de sorra de gats?

- A dalt 3 màquina granuladora de sorra de gats en venda a SX

- How long does it cost to produce cat manure?

- Successful Case of Cat Litter Manufacturing Plant Built by YUSHUNXIN

- What other materials can cat litter production line produce?