On 6,13, 2025, a Moroccan customer reached out to YUSHUNXIN. He is looking to build a 5 tons/hour cat litter manufacturing plant using locally mined bentonite. At the same time, his goal was to produce high-quality, eco-friendly bentonite cat litter for the domestic and North African markets. To meet this need, we designed a customized cat litter making machine line, starting with raw material pretreatment. Below are the details of our communication.

How Do We Process Bentonite Ore for Cat Litter Granulation in Morocco?

The customer from Morocco plans to want to buy the cat litter making machine with a capacity of 5 tons/hour. His raw material is natural bentonite ore, with a moisture content of about 12% and particle size over 10 mm.

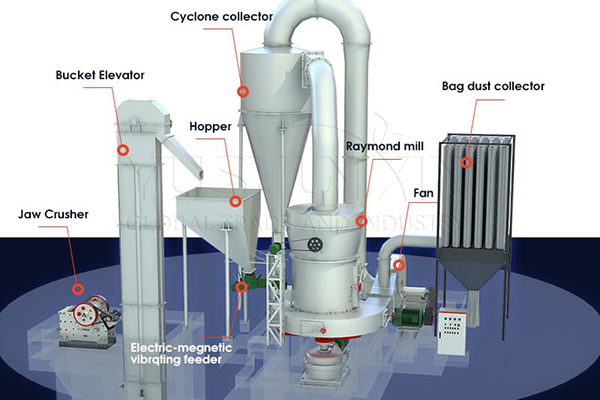

To ensure smooth Kitty litter granulation, we recommended a full pre-treatment process. First, dry the raw ore to reduce the moisture to 8–10%, making it suitable for crushing. Then, a raymond mill grinds the dried bentonite into fine powder under 200 mesh. This particle size is ideal for feeding into a bentonite cat litter machine. In addition, we has equipped a screening system removes stones and impurities before grinding. This pre-processing line not only stabilizes production but also improves the final cat litter quality.

Turnkey Cat Litter Production Solution by YUSHUNXIN for 5 TPH Capacity in Morocco

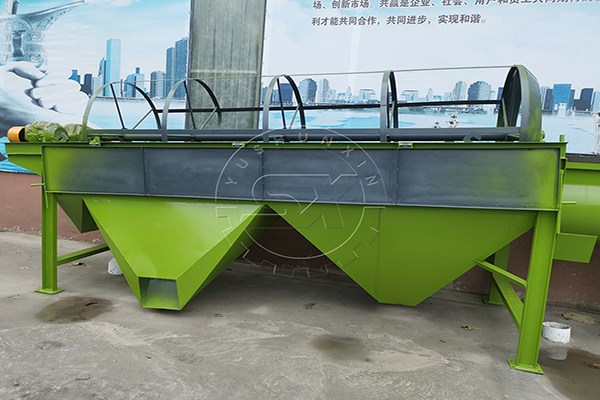

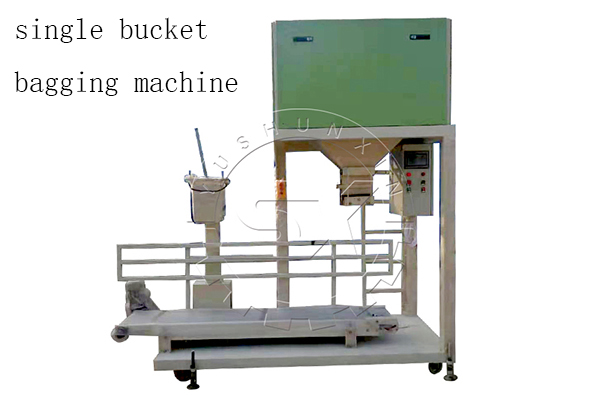

To meet the client’s 5 t/h capacity requirement, on the basis of pre-trement, we provided a turnkey cat litter production solution. The following equipment was included in the automatic cat litter making line:

YUSHUNXIN also can customize other affordable cat litter making equipment according to your capacity, budget. Feel free to contact us!

What is the cost to establish the 5 TPH cat litter manufacturing plant in Morocco?

Final, the total cost of the Morocco 5 TPH cat litter manufacturing solution reached $65,957. This includes all core equipment—from the bentonite grinding system to the automatic packing unit. In addition to equipment, we also considered key operating factors:

The data is for reference only and needs to be calculated based on your local conditions.

YUSHUNXIN Ensures Efficient Delivery of Cat Litter Production Line to Morocco

Once the production plan was finalized, YUSHUNXIN arranged the manufacturing and packaging of the complete 5 TPH cat litter making machine. Finally, the entire shipment was dispatched within 25 working days. With the help of our experienced logistics team, the equipment arrived at the Moroccan site in approximately 10-15 days by sea. Upon arrival, our technical engineers provided remote guidance and installation support, ensuring the 5 tons/hour cat litter manufacturing line smooth assembly and test runs.