In November 15, 2025, YUSHUNXIN received an inquiry from a fertilizer distributor in United Arab Emirates (UAE). The client planned to build a 20 T/H BB fertilizer production plant to supply the local and regional market. At the early stage, the customer focused strongly on the BB fertilizer plant cost, production capacity, and site utilization. According to the customer’s requirements, we successfully designed and delivered a complete 20 T/H BB fertilizer production line.

The following are the specific details of our communication in this case.

The customer background of seeking the 20 T/H BB fertilizer plant cost plan:

The main requirement of The UAE’S customer was clear from the beginning: high output with a limited budget of $150,000. They already had a warehouse and stable raw material suppliers for NPK granules. Instead of producing compound fertilizer through granulation, he wanted a simple and reliable BB fertilizer blending solution. After several online meetings, the client shared his target capacity, fertilizer formulas, packaging requirements, and site layout. Based on this information, our engineering team completed the technical proposal within two weeks. The project moved quickly from inquiry to final confirmation.

Is It Possible to Build a 20 T/H BB Fertilizer Plant Under $150,000 in UAE?

Yes, this project is fully achievable, and the key lies in the BB fertilizer production process itself.

Simple BB fertilizer production process for the customer from UAE

BB fertilizer production uses physical blending technology, not chemical reactions or granulation. This means the production line does not require dryers, coolers, granulators, or coating systems. As a result, the BB fertilizer plant cost remains much lower than that of traditional compound fertilizer plants.

For this UAE project, YUSHUNXIN focused on:

- Reducing unnecessary equipment

- Improving blending efficiency

- Ensuring stable continuous operation at 20 tons per hour

Because the simple process and low energy consumption, the total investment stayed well within budget. The final transaction price for this 20 T/H BB fertilizer plant was USD 121,090. So it is cost-effective and scalable solution for the customer in UAE.

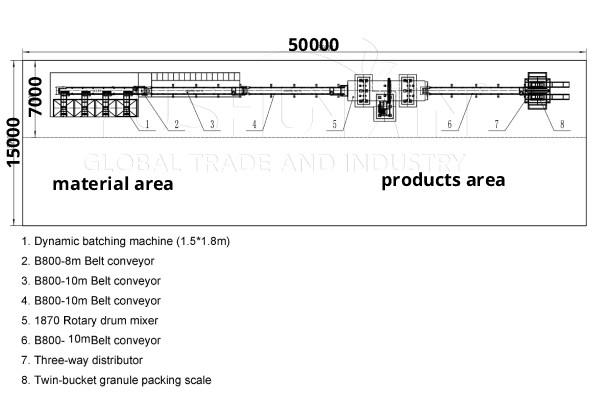

BB Fertilizer Equipment Configuration for the UAE Project

On the basis of the client’s formulas and production goals, YUSHUNXIN customized the fertilizer blending system with a capacity of 20 tons per hour.

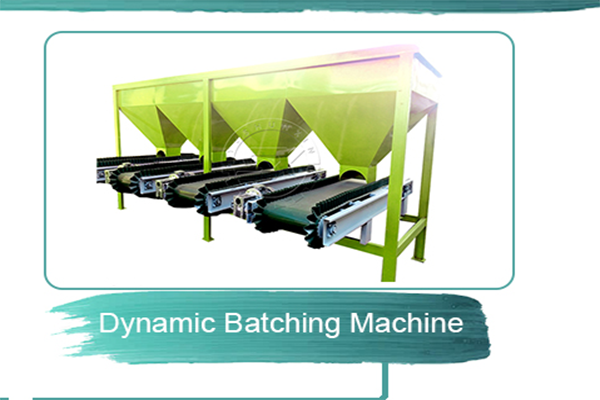

Dynamic batching machine–accurately batching materials

The 20 T/H bulk blending fertilizer production line starts with a dynamic batching system. This system allows different NPK raw materials (MOP, ammonium sulfate, phosphate (P2O5), and trace elements…) to feed into the line at controlled speeds. At the same time, it ensures accurate ratios for each fertilizer formula and supports quick adjustments.

BB Fertilizer mixing equipment

Next comes the BB fertilizer blending machine, which is the core of the entire line. The mixer provides uniform blending without breaking fertilizer granules. It maintains particle integrity while achieving high mixing efficiency. This design supports stable 20 T/H output during continuous operation.

Automatic bagging scale

At the final stage, an automatic packing system handles weighing and bagging. This reduces labor demand and improves packing accuracy. It also supports standard fertilizer bag sizes for the UAE market, which helps with logistics and distribution.

How Can One BB Fertilizer Line Produce Different NPK Formulas?

During the discussion, the UAE client raised a practical concern about formula flexibility. He explained that the project would start with NPK 20-10-10 and later shift to NPK 15-15-15. His key question was whether one production line could handle different formulas without increasing the BB fertilizer plant cost or reducing output.

To meet this demand, YUSHUNXIN equipped the plant with a dynamic batching machine. Which designed for high-capacity BB fertilizer blending. The system uses frequency-controlled belt feeders with PLC control and electronic weighing units with ±0.2% accuracy. Each raw material feeds independently, so operators can adjust feeding ratios directly from the control panel.

This setup allows the customer to switch formulas quickly, without mechanical modifications or long downtime. Whether producing NPK 20-10-10 or 15-15-15, the total output remains stable at 20 T/H. It ensures consistent BB fertilizer quality and efficient production under a limited budget.