Vào tháng 11 25, a customer from Uganda contacted us with a clear goal: upgrade an existing composting site and start producing compost fertilizer granules for sale. The raw material was mature compost, and the total budget was strictly controlled at USD 180,000. After several technical discussions, Yushunxin designed a practical compost fertilizer production plant that focused on equipment upgrade, granulation efficiency, and cost control. The following are the details of our communication.

What is the background of the Ugandan client Project and key Requirements?

The customer in Uganda already had basic composting experience. He told us ” We need to make compost 10.000 ĐẾN 30.000 tons per year, so we need the capacity per hour around 3-6 tấn. Their original system relied on a fixed groove type compost turner and manual handling. Except for upgrading composting machine, the customer wanted to:

- Convert loose compost into granulated organic fertilizer

- Control total investment within USD 180,000

- Ensure stable output of 3–6 T/H

Compost Equipment Upgrade: From Groove Type Turner to Crawler Compost Turner

At the early stage of this compost fertilizer production project, the customer was using a traditional groove type compost turner. While this equipment can handle basic compost fermentation, it gradually became insufficient as production demand increased. More importantly, the groove composting system could not easily adapt to changes in compost volume or site layout. It will affect compost uniformity, and overall fermentation speed and the following quality of compost fertilizer granulation.

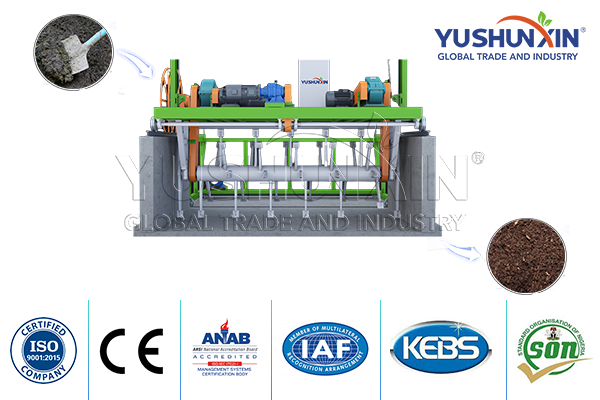

Economical crawler type compost machine

After evaluating the customer’s site conditions and target capacity, YUSHUNXIN recommended upgrading to a crawler compost turner. các crawler type compost turner offers much higher flexibility compared with groove systems. It works well in open compost yards and does not require fixed civil construction. This allows the customer from Uganda to adjust compost rows freely and scale up production when needed.

By upgrading the compost turning equipment, the customer significantly improved compost maturity consistency. This created a stable foundation for the following compost fertilizer granulation process.

Compost Fertilizer Granulation Equipment Selection

For the Uganda compost fertilizer production plant, choosing the right granulation machine was essential to meet the 3–6 T/H capacity target within a USD 180,000 ngân sách. Based on the compost characteristics and the customer’s operating requirements, YUSHUNXIN proposed two granulation solutions for evaluation.

Option 1: Stirring Tooth Organic Fertilizer Granulator

Đầu tiên, we introduced a stirring tooth organic fertilizer granulator as an alternative option. This machine relies on mechanical agitation rather than extrusion pressure. It does not require drying before granulation and works well with compost materials containing fibers and uneven moisture. It is a practical solution for compost fertilizer granulation under stable operating conditions.

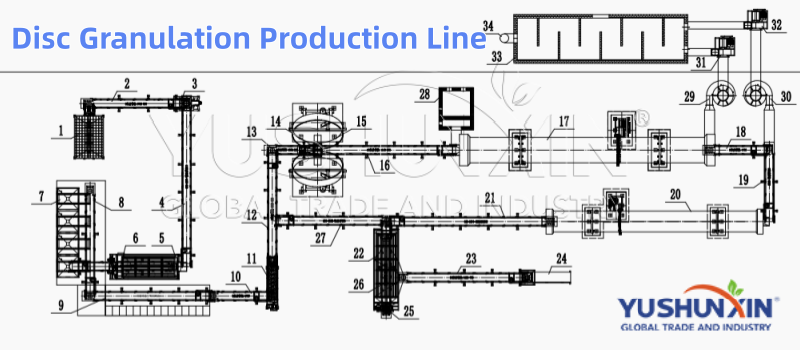

Disc Granulator – Best Choice for Compost Fertilizer Granulation in Uganda

The compost raw material used in this project has moderate moisture content and contains plant fibers. MỘT máy tạo hạt dạng đĩa handles this type of compost effectively and offers strong operational flexibility. During production, operators can clearly observe the granulation process and adjust parameters in real time.

After comparison, the customer finally selected the disc granulator. Its simple operation, visible granulation performance, and flexible particle size control fully met the current production needs. Cũng, the customer can add the benefical microorganism with it. Ngoài ra, this solution allows future expansion. When production capacity increases, the Uganda client can add a rotary drum granulator to build a larger compost fertilizer granulation line without replacing existing equipment.

Auxiliary Equipment Included in 6 TPH compost fertilizer production plant

In addition to the core granulation machine, YUSHUNXIN supplied a full set of supporting equipment for the Uganda compost fertilizer project. The USD 180,000 investment covered all essential auxiliary machines needed for stable and continuous production.

Main supporting equipment included:

With this configuration, the customer received a complete compost fertilizer production line instead of a single granulation unit. After installation, the plant could enter commercial operation immediately, without additional equipment investment.

Là một nhà máy nguồn, YUSHUNXIN can offer you an economical price when buy fertilizer equipment for compost pellets making. If you want to get the precise quote for industrial composting equipment you need and even fertilizer granule making machine price, Chào mừng bạn liên hệ với chúng tôi ngay bây giờ!