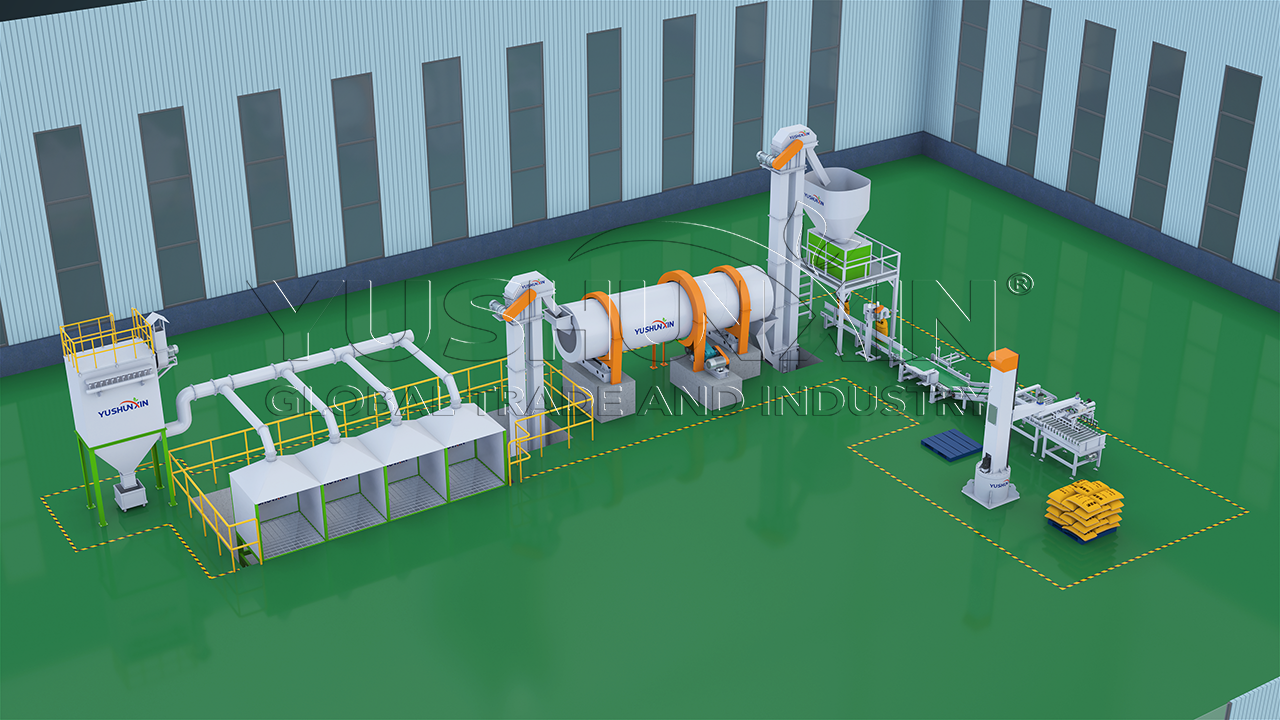

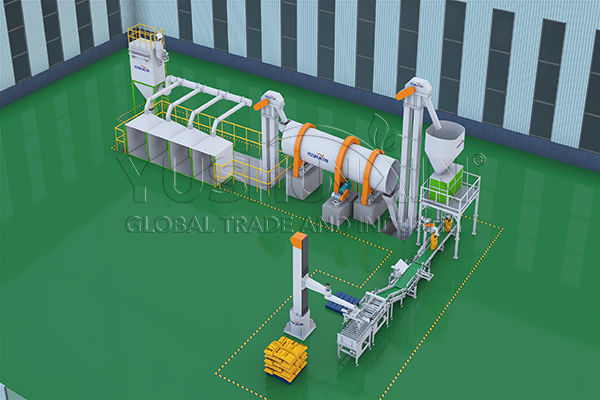

Eine Linie zur Massenmischung von Düngemitteln ist ein hocheffizientes System zur Herstellung maßgeschneiderter NPK-Düngemittelmischungen durch Dosierung, mischen, und Verpackungsprozesse. Im Gegensatz zu Herstellung von Mehrnährstoffdüngern, Der Schwerpunkt dieser Linie liegt auf der Dosierung und Mischung verschiedener körniger Düngemittel nach spezifischen Nährstoffformeln. Mit geringen Investitionen, kurze Bearbeitungszeit, und einfache Bedienung, Es ist zur idealen Wahl für Düngemittellieferanten geworden. Holen Sie sich noch heute Ihre Ausrüstung für die Massenmischung von Düngemitteln.

So starten Sie eine Produktionslinie für Massendüngermischungen: Schritt-für-Schritt-Anleitung

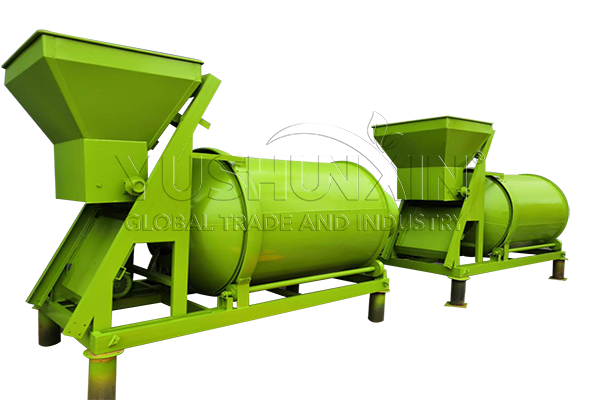

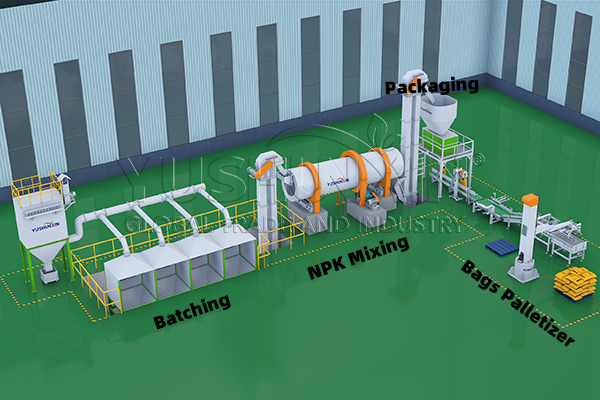

Nach der Dosierung der Rohstoffe, Das Förderband transportiert den Dünger zur gleichmäßigen Mischung in einen BB-Düngermischer. Durch den Mischvorgang kann eine gleichmäßige Verteilung der Düngemittel gewährleistet werden. Und das ist sehr wichtig, um die Homogenität des BB-Düngers aufrechtzuerhalten.

Nach dem Mischen, Der letzte Schritt bei der Herstellung von BB-Düngemitteln ist das Verpacken. Sie können a verwenden Düngemittelverpackungslinie den Dünger in gleiche Portionen aufteilen. Es erleichtert die Lagerung und den Transport.

Preis der Produktionslinie für Massendüngermischungen: Wie viel kostet es? 2025?

Der Preis einer Produktionslinie für die Massenmischung von Düngemitteln ist viel niedriger als der anderer Düngemittelproduktionssysteme, wie die Produktionslinie für Mehrnährstoffdünger, oder Produktion organischer Düngemittel, Produktionslinie für Biodünger. Dies liegt daran, dass die Herstellung von BB-Düngemitteln einfach zu bedienen ist und weniger Verarbeitungszeit erfordert.

Eine BB-Düngemittelfabrik kostet normalerweise ca $5,000 Zu $300,000, Dies dient nur zu Ihrer Information. Wenn Sie über den Kauf einer Produktionslinie für die Massenmischung von Düngemitteln nachdenken, Sie sollten mehrere Faktoren berücksichtigen, wie etwa die Gerätefunktionen, Grad der Automatisierung, Produktionskapazität, und andere spezifische Anforderungen. Der Endpreis kann je nach Ihrem tatsächlichen Bedarf variieren.

Grundlegende Ausrüstung für die Herstellung von Massendüngermischungen

Aufgrund des einfachen Prozesses der Massenmischung von Düngemitteln, Düngemittellieferanten benötigen nur drei Haupttypen von Ausrüstung: eine Dosiermaschine, eine BB-Düngermischmaschine, und Verpackungswaagen für Düngemittel. Außerdem, Yushunxin können diese Maschinen kostenlos an Ihre spezifischen Produktionsanforderungen anpassen.

So stellen Sie verschiedene BB-Düngemittel mit einer Bulk-Mischdüngerlinie her?

Viele Düngemittellieferanten möchten unterschiedliche BB-Düngemittelformeln herstellen, wie zum Beispiel 20-20-20, 15-15-15, oder andere kundenspezifische Verhältnisse. In der Praxis, das ist nicht kompliziert. Eine flexible und genaue Düngerdosiermaschine ist der Schlüssel. Denn die Herstellung von BB-Düngemitteln beruht auf der physikalischen Mischung. Seine Rohstoffe behalten ihre ursprüngliche Partikelform. daher, Das endgültige Nährstoffverhältnis hängt vollständig vom genauen Wiegen und der Kontrolle der Proportionen ab.

-

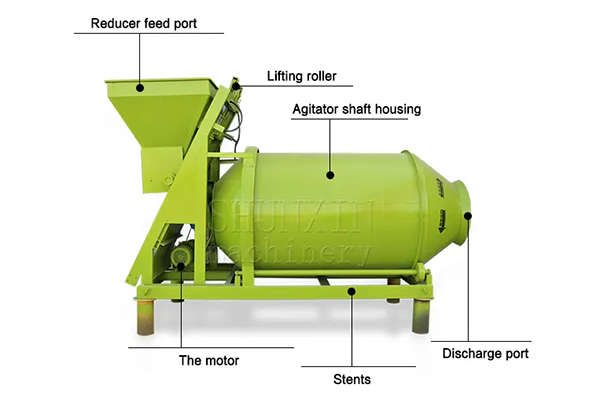

BB-Düngemittel-Dosiermaschine – die Schlüsselausrüstung in einer Linie zur Massenmischung von Düngemitteln

BB-Düngemittel-Dosiermaschine – die Schlüsselausrüstung in einer Linie zur Massenmischung von Düngemitteln

Bediener können Formeln schnell ändern, z 20-20-20, 15-15-15, oder 10-26-26 durch das Steuerungssystem. Dieses Design reduziert Ausfallzeiten, verbessert die Produktionseffizienz, und minimiert manuelle Fehler.

Welche Rohstoffe werden bei der Herstellung von Massendüngermischungen verwendet??

Die Produktion von Massendüngermischungen wählt körnige Rohstoffe basierend auf ihrem N aus, P, und K-Nährstoffgehalt. Sie können verschiedene Formeln erstellen, wie zum Beispiel 20-20-20 oder 15-15-15 durch Anpassen des Anteils jeder Nährstoffquelle.

Spitze 2 Vorteile einer Investition in eine Produktionslinie für Massendüngermischungen

Mit einer relativ geringen Investition, Eine Linie zur Herstellung von Massendüngern bietet eine praktische Lösung für Düngemittelhersteller, die eine hohe Produktion wünschen, niedrige Kosten, und schnellen Markteintritt. Die folgenden Vorteile erklären, warum sich immer mehr Investoren für Massenmischsysteme entscheiden.

Inhalt

- Comment démarrer une ligne de production d'engrais de mélange en vrac: Guide étape par étape

- Prix de la ligne de production d’engrais de mélange en vrac: Combien ça coûte en 2025?

- Équipement essentiel pour la fabrication d’engrais en vrac

- Comment fabriquer différents engrais BB avec une seule ligne d'engrais de mélange en vrac?

- Quelles matières premières sont utilisées dans la production d'engrais de mélange en vrac?

- Hoch 2 Avantages d’investir dans une ligne de production d’engrais de mélange en vrac