Uttrovi 20, 2025, un cliente da Bolivia hà cuntattatu YUSHUNXIN attraversu u nostru situ web. Hà pensatu à investisce USD 350,000 per custruisce un NPK Line di pruduzzione fertilizante cù una pruduzzioni annuale di circa 300,000 tunnellate. Dopu à u calculu, a capacità di destinazione raggiunta intornu 10 tunnellate per ora. E materie prime principali includenu urea, fosfat di diammoniu (DAP), è chlorur di potasio (KCl). Dopu una cumunicazione dettagliata nantu à a materia prima, capacità, e esigenze ambientali lucali, YUSHUNXIN hà cuncepitu a 10 Soluzione di fertilizante T/H NPK chì equilibra a pruduzzioni stabile, qualità di u produttu, è cunfurmità ambientale.

Pudete furnisce noi 10 Linia di pruduzzioni di fertilizzanti TPH NPK à $350,000?

Per scuntrà u scopu di u cliente bolivianu di a 10 Linea di pruduzzione di granulazione di fertilizzanti TPH NPK in a $350,000 budget, YUSHUNXIN hà cuncepitu una soluzione cumpleta è cuntrullata à i costi basata in urea, fosfat di diammoniu (DAP), chlorur di potasio (KCl), è oligoelementi.

Trituratore di urea ($4,600- 5 600 $)

Primu, un trituratore di urea riduce i granuli di urea è DAP in polvere fine. Dopu à sfracicà, a dimensione di particella righjunghji ≤1 mm, senza particelle grandi rimanenti. Stu passu migliurà a dispersione di materiale, aumenta l'uniformità di mischju, è assicura rapporti NPK precisi.

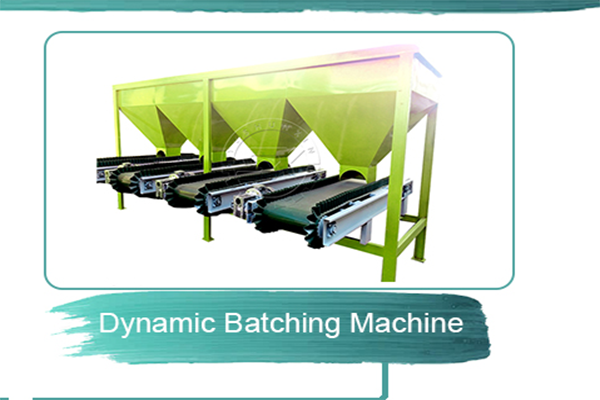

Sistema automaticu di batching ($4,000- 5 500 $)

Dopu, a scala automatica di batching pesa precisamente urea, DAP, KCl, è micro-nutrienti. Supporta u batching simultaneo di 3-10 materie prime, cù una precisione di pesata finu à ± 0,5%. In più, l'alarma di mancanza di materia prima aiuta à prevene l'errore di formulazione durante u funziunamentu cuntinuu.

Mixer horizontale à double arbre ($3,500- 4 500 $)

U miscelatore horizontale à duppiu albero mischja tutte e materie prime in modu uniforme prima di granulazione. L'uniformità di mischju righjunghji ≥95%, senza zone morte. Tratta i polveri secchi è umidi è permette l'aggiunta più tardi di additivi liquidi, cum'è agenti anti-caking o agenti microbiani.

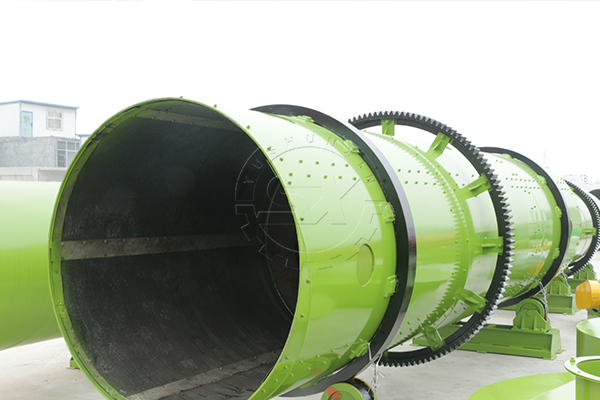

Granulatore a tamburo rotante ($30,000- 35 000 $)

I materiali misti allora entra in u SXZGZ-2028 granulatore a tamburo rotante. Questa macchina forma granuli di fertilizzanti NPK forti è uniformi per a produzzione cummerciale à grande scala. A so rata di granulazione supera 98%, è l'operatori ponu aghjustà a dimensione di particella cambiendu a velocità di u tamburu è l'inclinazione.

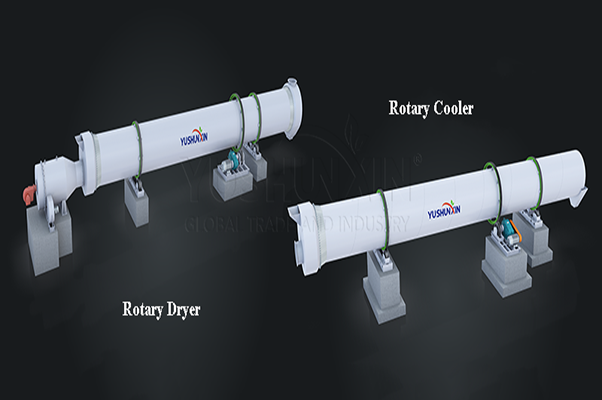

Unità di Asciugatura è Raffreddamentu (circa $80,000)

Per migliurà a forza di granuli è cuntrullà l'umidità, avemu cunsigliatu a 1.2 × 2 m machine à asciugà è rinfriscà. Questa unità stabilizza a qualità di u fertilizzante è sustene a pruduzzione continua di 10 tunnellate per ora.

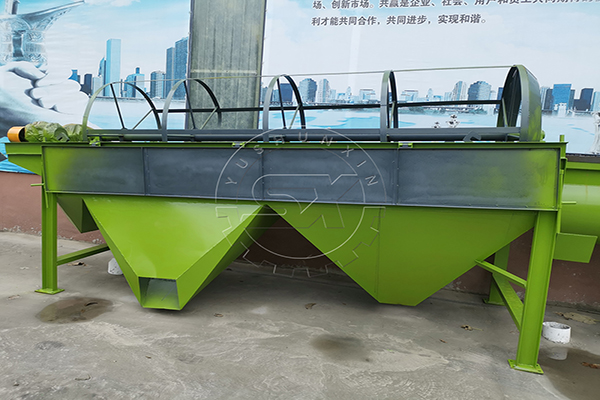

Macchina di vagliatura di tamburi rotanti ($8,000- 9 000 $)

Dopu à secca, u SXZG-1560D vagliatore a tamburo rotante separa i granuli qualificati da e particelle grandi è fini. U so disignu di schermu multi-layer permette a classificazione simultanea. I granuli oversized tornanu à u crusher, mentre chì a polvera fina torna in u granulatore, furmendu un sistema di ciclu chjusu.

Macchina d'imballaggio à doppia bucket ($10,000- 12 000 $)

- Infine, a scala d'imballaggio a doppia seca è i trasportatori à cinturione cumplenu a pesa è l'imballazione automatica, preparazione di fertilizante NPK finitu per u almacenamentu è a distribuzione.

- A 2 × 2 m buffer silo equilibra u flussu di materiale trà prucessi è assicura liscia, operazione ininterrotta.

Questu 10 A linea di produzzione di fertilizzanti TPH NPK risponde cumpletamente à a capacità di u cliente bolivianu, materia prima, e esigenze di bilanciu mentre furnisce un rendimentu stabile è una produzzione di fertilizzanti di alta qualità.

Cumu uttene granuli di fertilizante NPK culuriti è d'alta resistenza (≥ 12 N)?

U cliente in Bolivia hà ancu bisognu di granuli di fertilizante NPK multicolore cù una forza di triturazione di almenu 12 N, destinatu à u mercatu di fertilizzanti premium.

Macchina per arrotondare a pellet

arrotondatrice a pellet

Per risponde à questu requisitu, Avemu cunsigliatu per aghjunghje una macchina di arrotondamentu di pellet dopu a tappa di granulazione di tamburi. Stu equipamentu rimodella particelle irregulari in granuli più tondi è uniformi, migliurà significativamente a sfericità è a liscia di a superficia. Di cunsiguenza, i granuli mostranu una dimensione consistente è un aspettu visuale megliu.

Macchina di rivestimentu di tamburi

Macchina di rivestimentu di tamburi

In più, avemu equipatu u 300,000 Linea di pruduzzioni di fertilizzanti TPY NPK cun una macchina di rivestimentu di fertilizzanti. U sistema di rivestimentu applica uniformemente agenti di culore è additivi funziunali nantu à a superficia di granule. Ùn pruduce micca solu prudutti di fertilizzanti NPK culuriti, ma aumenta ancu a durezza di granuli, riduce a polvera durante a manipulazione, è migliurà a prestazione di almacenamento è trasportu.

Dopu a prova in situ, i granuli di fertilizzanti NPK finiti anu ottinutu una forza di frantumazione di ≥12 N, cumplettamente cumplettamente i standard di qualità di u cliente da Bolivia.

Cume avemu aiutatu u cliente in Bolivia à cuntrullà l'emissioni di polvera è acque di scarico?

U cliente bolivianu hà ancu affruntatu rigulamenti lucali stretti nantu à u cuntrollu di polvera è scarico di l'acqua residua. Per assicurà u cumpletu cumpletu, YUSHUNXIN integratu un sistema efficace di prutezzione di l'ambiente in u 300,000 tunnellate/annu pianta granulazione di fertilizante NPK.

Per a gestione di polvera, avemu installatu un cullettore di polvera di saccu di impulsu in i punti chjave di generazione di polvera, cum'è sfracicà, mischjendu, e sezioni di screening. Stu sistema cattura particelle fini di fertilizzanti in tempu reale è mantene a cuncentrazione di polvera ben sottu à i limiti di emissioni lucali. Migliura ancu l'ambiente di l'attellu è prutegge a salute di i travagliadori.

Per u cuntrollu di l'acqua, avemu cuncepitu un sistema di riciclamentu di l'acqua residuale in ciclu chjusu. Tutta l'acqua di pulizia è l'acqua residuale di prucessu torna in un tank di raccolta per a riutilizazione in granulazione è mischju. cusì, stu disignu ottene un scaricamentu d'acqua residuale quasi zero è riduce u cunsumu d'acqua fresca.

Cù sti sistemi, lu 300,000 A pianta di fertilizzanti TPY NPK risponde à i standard ambientali mantenendu stabile, pruduzzione cuntinuu.